Flat knitting machines are revolutionizing the textile industry, offering unparalleled versatility, precision, and efficiency in creating high-quality knitted fabrics. Whether you’re a seasoned textile manufacturer, a fashion designer, or a hobbyist looking to explore advanced knitting technology, understanding how to operate a flat knitting machine is essential. This comprehensive 5000-word guide will walk you through the intricacies of flat knitting machines, their applications, and step-by-step instructions on how to operate them effectively. We'll also highlight why Changhua's flat knitting machines are a top choice for professionals and businesses worldwide.

What is a Flat Knitting Machine?

A flat knitting machine is a textile manufacturing device designed to produce flat, weft-knitted fabrics. Unlike circular knitting machines that create tubular fabrics, flat knitting machines produce flat panels, making them ideal for garments like sweaters, scarves, cardigans, and technical textiles. These machines are highly versatile, capable of creating intricate patterns, textures, and even seamless garments with advanced models.

Flat knitting machines come in two main types: manual (or semi-automatic) and computerized. Manual machines require operators to adjust settings and patterns, while computerized versions use advanced software for precise control, enabling complex designs with minimal manual intervention.

Applications of Flat Knitting Machines

Fashion Industry

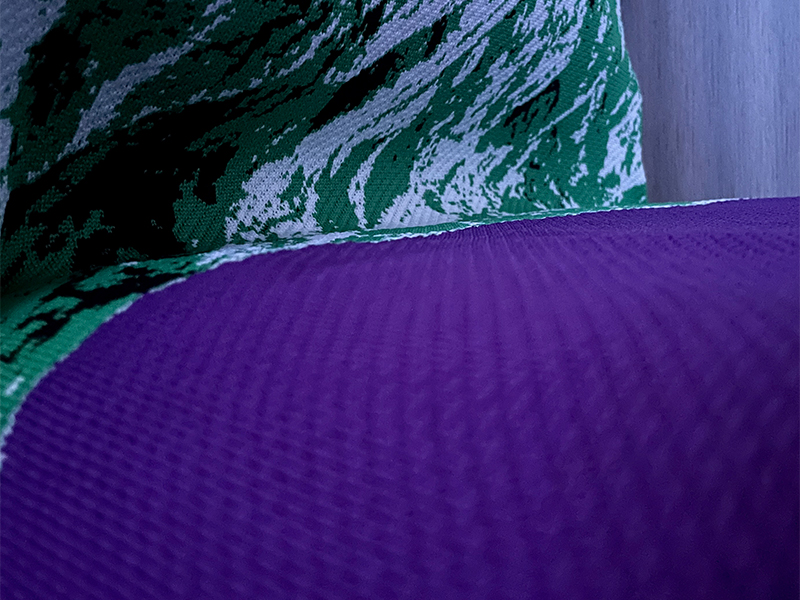

Producing sweaters, cardigans, scarves, and other knitwear with intricate patterns and textures.

Sportswear

Creating breathable, flexible fabrics for athletic wear.

Automotive and Aerospace

Producing technical textiles for upholstery and composite materials.

Home Furnishings

Crafting blankets, upholstery, and decorative textiles.

Understanding the Components of a Flat Knitting Machine

Needle Beds

Flat knitting machines typically feature two stationary needle beds arranged in an inverted V-shape (also known as V-bed machines). These beds house latch-hook or bearded needles that move within tracks to form stitches.

Carriage or Cam Box

The carriage moves across the needle beds, controlling needle movements to create stitches. It houses cams that dictate whether needles knit, tuck, or miss, allowing for pattern creation.

Yarn Feed System

Yarn is fed from bobbins through a creel, tensioners, and yarn guides. A yarn length compensator ensures consistent tension, preventing defects in the fabric.

Computer Control System (for Computerized Machines)

Scarves, gloves, and hats with intricate patterns.

Take-Down System

This system pulls the knitted fabric downward, maintaining consistent tension and ensuring smooth production.

Sensors and Motors

In advanced models, sensors monitor yarn consumption and stitch formation, while motors automate needle movements and yarn feeding for seamless operation.

Benefits of Using Flat Knitting Machines

Flat knitting machines offer numerous advantages, making them a preferred choice for textile manufacturers:

Versatility

They can produce a wide range of patterns, textures, and 3D structures, including seamless garments.

Efficiency

Computerized machines significantly reduce production time compared to hand knitting or manual machines.

Precision

Advanced control systems ensure consistent stitch quality and accurate dimensions.

Sustainability

Touchscreen controls and CAD software integration make it easy to input and modify designs, supporting quick design changes for personalized production.

Customization

Operators can easily program custom designs, catering to niche markets and individual preferences.

Step-by-Step Guide to Operating a Flat Knitting Machine

Operating a flat knitting machine requires careful setup, programming (for computerized models), and maintenance to ensure optimal performance. Below is a detailed guide to help you get started.

Step 1: Prepare the Machine

Before operating the machine, ensure it’s ready for use:

Inspect the Machine: Check for any visible wear, damage, or debris. Clean the needle beds and carriage to remove dust or old grease. For older machines, lubricate moving parts as needed.

Select Yarn: Choose high-quality yarn suitable for your machine’s gauge (e.g., sock-weight yarn for standard-gauge machines). Ensure the yarn is wound properly to prevent tangling.

Set Up the Yarn Feed: Thread the yarn through the creel, tensioners, and yarn guides. Use the yarn length compensator to maintain consistent tension.

Power On: For computerized machines, turn on the control panel and ensure the software is updated.

Step 2: Program the Design (Computerized Machines)

For computerized flat knitting machines, programming is a critical step:

Use CAD Software: Input your garment pattern using compatible design software. Changhua machines support user-friendly CAD interfaces for creating complex designs.

Select Stitch Types: Choose from knit, tuck, miss, or transfer stitches to create your desired pattern.

Set Parameters: Adjust stitch length, yarn tension, and garment dimensions. Advanced systems like Changhua’s Digital Stitch Control System (DSCS) automatically calculate yarn consumption for precision.

Test the Pattern: Run a small test swatch to verify the design and make adjustments as needed.

Step 3: Cast On

Casting on sets the foundation for your knitted fabric:

Manual Machines: Manually position needles and loop yarn over them according to the pattern (e.g., cast on needles 36L to 36R for a balanced panel).

Computerized Machines: Use the machine’s auto-cast-on feature, which positions needles and feeds yarn automatically.

Check Tension: Ensure the yarn is fed smoothly without excessive slack or tightness.

Step 4: Start Knitting

Move the Carriage: For manual machines, move the carriage back and forth across the needle beds to form stitches. For computerized machines, the carriage operates automatically based on the programmed pattern

Monitor Progress: Watch for dropped stitches or yarn tangles. Computerized machines often have sensors to detect errors, but manual checks are still recommended.

Adjust as Needed: If the fabric appears uneven, adjust the stitch cam or yarn tension.

Step 5: Shape the Garment

Flat knitting machines excel at creating shaped garments:

Use Loop Transfer: Transfer stitches between needle beds to create shaping, such as narrowing for sleeves or widening for collars.

Incorporate Short Rows: For 3D shaping, use short rows to knit partial rows, creating curves or contours.

Seamless Knitting (Whole Garment): Advanced machines like Changhua's Whole Garment Flat Knitting Machines knit entire garments in one piece, eliminating the need for sewing.

Step 6: Finish and Remove the Fabric

Cast Off: Use the machine’s cast-off function or manually bind off stitches to secure the fabric.

Remove the Fabric: Gently pull the fabric from the take-down system, ensuring no stitches are dropped.

Inspect the Garment: Check for defects and trim any loose yarn ends.

Step 7: Maintain the Machine

Regular maintenance ensures long-term performance:

Clean Regularly: Remove lint, dust, and yarn residue from the needle beds and carriage.

Lubricate Moving Parts: Apply machine oil to the carriage and needle tracks as recommended by the manufacturer.

Check Components: Inspect needles, yarn guides, and sensors for wear and replace as needed.

Calibrate: Periodically recalibrate computerized machines to maintain accuracy.

Why Choose Changhua Flat Knitting Machines?

When it comes to flat knitting machines, Changhua stands out as a leading manufacturer with over 20 years of experience in the textile industry. Based in Changshu, Jiangsu, Changhua is renowned for its innovative, high-quality machines that cater to a wide range of applications, from fashion to technical textiles. Here’s why Changhua is the go-to choice for textile manufacturers worldwide:

Advanced Technology

Changhua's computerized flat knitting machines are equipped with cutting-edge features like Digital Stitch Control Systems (DSCS) and user-friendly CAD software. These technologies ensure precise stitch formation, minimal waste, and high efficiency.

Seamless Whole Garment Production

Changhua's Whole Garment Flat Knitting Machines produce seamless garments in a single operation, reducing production time and material waste. This technology is ideal for creating comfortable, high-quality knitwear for fashion, sportswear, and medical applications.

Sustainability Focus

Changhua is committed to sustainability, with machines designed to minimize waste and energy consumption. Their fast and intelligent programming enhances efficiency, making them an eco-friendly choice for modern manufacturers.

Comprehensive Support

Changhua offers on-site and online training to ensure operators can maximize the machine's potential. Their 24/7 technical support and average delivery time of 15-30 days make them a reliable partner for businesses.

Proven Track Record

With an annual output of over 6,000 machines and a reputation for durability and stability, Changhua’s machines are trusted by manufacturers worldwide. Their brands, including “Changhua,” “Tiangong,” “King Tiger,” and “Miao’s Craftsman,” are synonymous with quality.

Tips for Optimizing Flat Knitting Machine Performance

Use High-Quality Yarn

Low-quality yarn can cause tension issues and dropped stitches. Opt for yarn that matches your machine’s gauge and is free of knots or inconsistencies.

Regularly Update Software

For computerized machines, keep the software updated to access the latest features and bug fixes. Changhua provides regular updates to enhance machine performance.

Train Operators Thoroughly

Proper training is essential to prevent errors and maximize efficiency. Changhua offers comprehensive training programs to help operators master their machines.

Experiment with Patterns

Flat knitting machines are highly versatile, so don’t be afraid to experiment with new stitch patterns, textures, or 3D shaping techniques to create unique products.

Follow Safety Guidelines

Always wear appropriate safety gear and follow the manufacturer’s guidelines to prevent accidents. Ensure the machine is properly set up and calibrated before operation.

Conclusion

Learning how to operate a flat knitting machine opens up a world of possibilities for creating high-quality, customizable textiles. From fashion to technical applications, these machines offer unmatched versatility and efficiency. By following the steps outlined in this guide—preparing the machine, programming designs, casting on, knitting, shaping, and maintaining the equipment—you can master the art of flat knitting.

For those looking to invest in a reliable, high-performance flat knitting machine, Changhua is a trusted choice. With our advanced technology, sustainability focus, and comprehensive support, Changhua's machines are designed to meet the needs of modern textile manufacturers. Whether you're producing seamless knitwear, sportswear, or technical textiles, Changhua has the tools to help you succeed.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe