Small garment factories face unique challenges when it comes to selecting knitting machines. Unlike large-scale manufacturers, small factories often prioritize flexibility, cost-efficiency, and the ability to produce a diverse range of products in smaller quantities. Choosing the right knitting machine is critical to meeting these demands while maintaining high-quality output and staying competitive in the fast-paced textile industry. This article explores the key factors small garment factories should consider when selecting knitting machines, with a focus on small-batch and multi-variety production. We'll also highlight why Changhua's knitting machines are an excellent choice for such operations.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Are Knitting Machines?

Knitting machines are specialized equipment used to create knitted fabrics by interlocking yarn in a series of rows. Unlike hand knitting, which is time-consuming and labor-intensive, knitting machines automate the process, enabling faster production and consistent quality. These machines are essential for producing a wide range of products, including sweaters, scarves, hats, gloves, blankets, and even technical textiles like medical compression wear and automotive fabrics.

There are two primary types of knitting machines: flat knitting machines and circular knitting machines. Flat knitting machines produce flat fabric panels that are ideal for garments requiring assembly, such as sweaters and scarves. Circular knitting machines, on the other hand, create seamless tubular fabrics, perfect for items like socks, leggings, and t-shirts. For small garment factories focusing on small-batch and multi-variety production, flat knitting machines are often preferred due to their versatility and ability to handle intricate designs.

Applications of Knitting Machines in Small Garment Factories

Small garment factories typically cater to niche markets, custom orders, or limited-edition collections. The ability to produce a variety of products in small quantities is crucial for meeting customer demands and staying agile in a competitive market. Here are some key applications of knitting machines in small factories:

Fashion Industry: Small factories often produce high-quality, customized knitwear such as sweaters, cardigans, and scarves. Flat knitting machines excel at creating intricate patterns like jacquard, intarsia, and pointelle, which are popular in fashion apparel.

Sportswear and Athleisure: Seamless garments produced by whole garment knitting machines are ideal for sportswear, offering comfort and flexibility for athletic performance.

Accessories: Hats, gloves, and scarves are staples for small-batch production, as they require less material and can be produced quickly.

Home Textiles: Blankets, cushions, and decorative throws benefit from the texture and pattern capabilities of flat knitting machines.

Key Factors to Consider When Choosing Knitting Machines

Selecting the right knitting machine for a small garment factory involves balancing several factors. Below are the critical considerations to ensure the machine meets the needs of small-batch, multi-variety production:

1. Gauge and Yarn Compatibility

The gauge of a knitting machine refers to the number of needles per inch, which determines the fineness or thickness of the fabric. Small factories need machines that can handle a range of yarn types, from fine fingering weight to bulky yarns, to produce diverse products.

2. Automation Level

Knitting machines range from manual to fully computerized systems. For small factories, the level of automation is a critical decision:

Manual Machines: Affordable and suitable for very small operations or prototyping, but they require more labor and time, making them less efficient for scaling production.

Semi-Automatic Machines: Offer a balance between cost and efficiency, allowing operators to handle simple patterns with moderate automation.

Computerized Machines: Provide high precision, speed, and the ability to produce complex patterns with minimal manual intervention. These are ideal for small-batch production with frequent design changes.

3. Production Capacity and Speed

Small factories need machines that can produce small batches efficiently without compromising quality. Computerized flat knitting machines, especially those with high-speed capabilities, can significantly reduce production time. Features like motor-controlled carriages and dynamic stitch technology enhance efficiency, making them suitable for meeting tight deadlines.

4. Versatility for Multi-Variety Production

The ability to produce a wide range of patterns and textures is essential for small factories catering to diverse customer preferences. Machines with features like jacquard, intarsia, tuck, and pointelle capabilities allow factories to create unique designs without investing in multiple machines.

5. Ease of Use and Maintenance

For small factories with limited staff, machines should be user-friendly and easy to maintain. Computerized machines with touchscreen interfaces and automated features simplify operation, while regular maintenance tasks like cleaning and oiling ensure longevity. Choosing a supplier with reliable after-sales support and readily available spare parts is also crucial.

6. Cost and Budget

Small garment factories often operate on tight budgets, so the initial investment in a knitting machine must be weighed against long-term benefits. While computerized machines have a higher upfront cost, their efficiency and versatility can lead to significant savings over time. Additionally, consider the cost of accessories, training, and maintenance when budgeting.

7. Sustainability and Waste Reduction

Sustainability is increasingly important in the textile industry. Machines that minimize yarn waste, such as whole garment flat knitting machines, are ideal for small factories aiming to reduce environmental impact while keeping production costs low.

Why Choose Changhua Knitting Machines?

For small garment factories looking for reliable, versatile, and efficient knitting machines, Changhua stands out as a leading manufacturer. With over 20 years of experience, Changhua offers a range of computerized flat knitting machines designed to meet the needs of small-batch and multi-variety production. Our machines are engineered for precision, durability, and flexibility, making them an excellent choice for small factories.

Changhua's Computerized Flat Knitting Machines

Changhua's computerized flat knitting machines are equipped with advanced features that cater to the demands of small garment factories. Here are some highlights:

Double System Technology: Changhua's double system machines feature high rollers, high-performance sinkers, and dynamic stitch technology. These features enable the production of complex patterns like pointelle, tuck, jacquard, intarsia, and full needle jacquard, suitable for a wide range of yarns, including wool, cashmere, cotton, silk, and blended fibers.

Whole Garment Capabilities: Changhua's whole garment flat knitting machines produce seamless garments in a single process, reducing fabric waste and eliminating the need for sewing. This is particularly valuable for small factories producing high-quality, custom-fit clothing for fashion, sportswear, or medical applications.

High Efficiency and Speed: With motor-controlled carriages and digital technology, Changhua machines offer high-speed production and excellent stability. Features like bilateral needle closure and zero-waiting racking ensure efficient knitting, even for intricate designs.

Durability and Low Maintenance: The needle plate is automatically oiled to reduce wear, extending the machine’s lifespan. Changhua also provides comprehensive training and 24/7 technical support, ensuring smooth operations.

Specific Models for Small-Batch Production

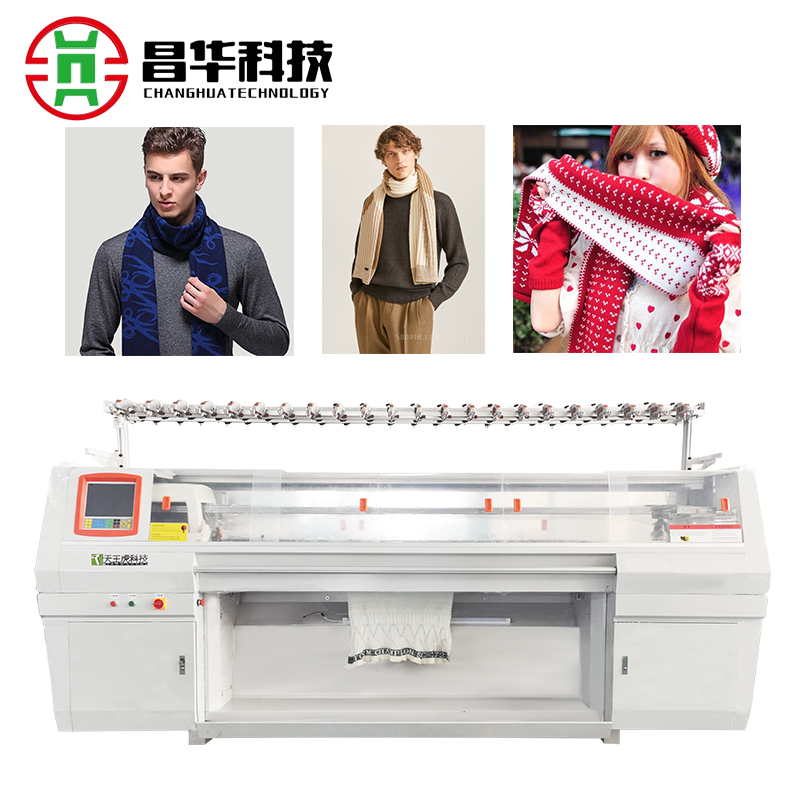

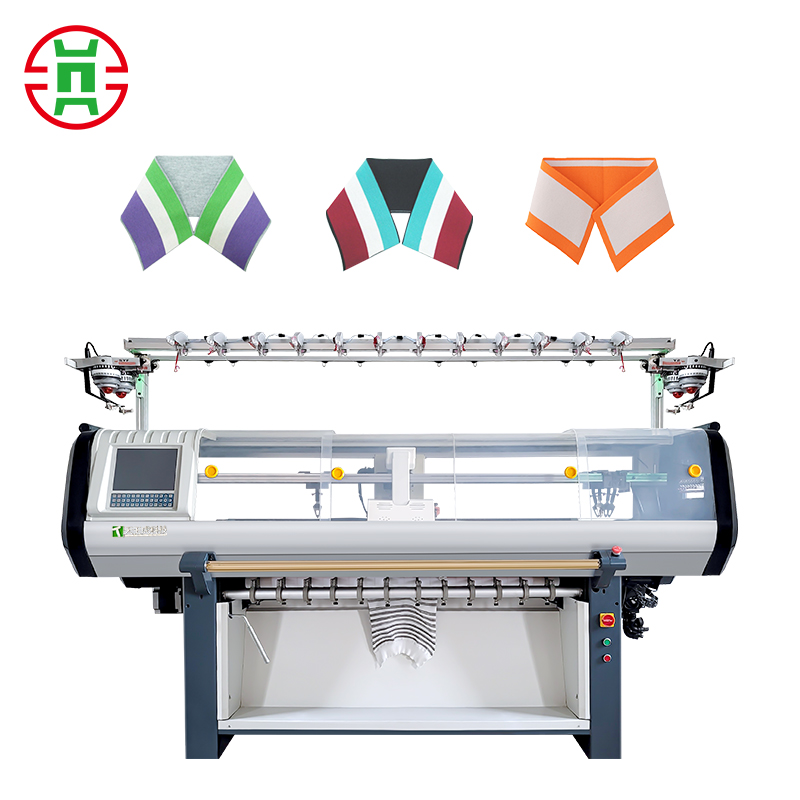

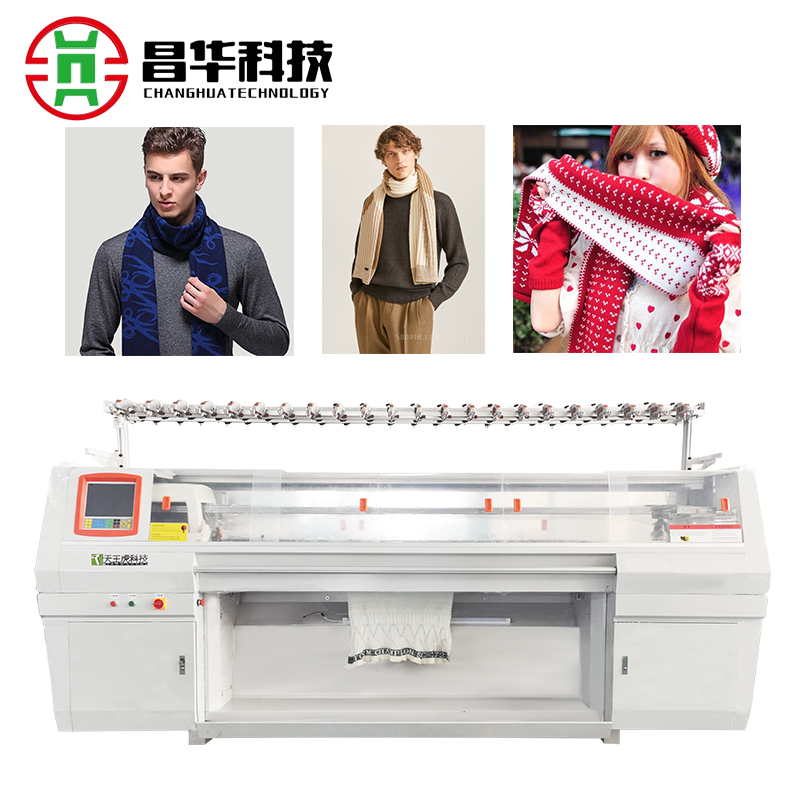

Changhua offers a variety of models tailored to small-batch and multi-variety production, including:

Sweater Knitting Machine: Ideal for producing high-quality sweaters with intricate patterns.

Collar Knitting Machine: Designed for precision in creating ribbed, flat, or jacquard collars, perfect for small factories focusing on garment details.

Whole Garment Flat Knitting Machine: Produces seamless garments, reducing waste and labor costs.

Scarf and Hat Knitting Machines: Specialized for accessories, allowing quick production of small batches.

Why Changhua Stands Out

20+ Years of Expertise: Based in Changshu, Jiangsu, Changhua has a strong reputation for innovation and quality in the textile industry.

Global Client Base: Trusted by brands in Europe, the USA, and Asia, Changhua machines are proven to meet international standards.

Customizable Solutions: Changhua offers tailored solutions for small factories, including training and after-sales support.

Sustainability Focus: Their whole garment machines minimize yarn waste and support eco-friendly yarns, aligning with sustainable production goals.

Practical Tips for Small Garment Factories

1. Assess Your Production Needs

Before purchasing a knitting machine, evaluate the types of products you plan to produce, the volume of orders, and the level of customization required. For small-batch, multi-variety production, prioritize machines with flexible gauge settings and pattern capabilities, like Changhua's computerized models.

2. Invest in Training

Ensure your staff is trained to operate and maintain the machines. Changhua provides on-site and online training to help operators master their equipment, reducing errors and downtime.

3. Plan for Maintenance

Regular maintenance, such as cleaning lint and oiling moving parts, is essential to keep machines running smoothly. Changhua's machines are designed for low maintenance, with features like automatic needle plate oiling.

4. Start with a Versatile Machine

If budget is a concern, start with a single computerized flat knitting machine that can handle multiple product types. Changhua's whole garment machines are a great option for maximizing versatility.

5. Consider Scalability

Choose a machine that can grow with your business. Changhua's range of machines allows factories to start with one model and expand to additional specialized machines as production needs increase.

Conclusion

Choosing the right knitting machine is a pivotal decision for small garment factories aiming to succeed in small-batch and multi-variety production. By considering factors like gauge, automation, versatility, and maintenance, factories can select equipment that aligns with their production goals and budget. Changhua's computerized flat knitting machines offer an ideal solution with our advanced features, durability, and support for sustainable production. Whether you're producing sweaters, scarves, collars, or seamless sportswear, Changhua's machines provide the flexibility and efficiency needed to thrive in the competitive textile market.

For more information or to request a quote, contact Changhua today and elevate your small garment factory's production capabilities.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe