In today's competitive apparel industry, clothing enterprises face relentless pressure to reduce production costs while meeting consumer demands for sustainable, high-quality products. Whole garment flat knitting machines have emerged as a game-changing technology, enabling manufacturers to streamline sweater production, minimize waste, and embrace eco-friendly practices. This article explores how these innovative machines achieve cost savings, their applications across various sectors, and why Changhua's whole garment flat knitting machines are the ideal choice for modern textile businesses. By leveraging zero-waste manufacturing and advanced automation, these machines address the cost control needs of clothing enterprises while aligning with global sustainability trends.

What Are Whole Garment Flat Knitting Machines?

Whole garment flat knitting machines represent a revolutionary advancement in textile manufacturing. Unlike traditional knitting machines that produce separate fabric panels requiring cutting and sewing, whole garment machines create seamless, three-dimensional garments directly from yarn in a single process. Pioneered by companies like Shima Seiki in 1995, this technology eliminates the need for post-production assembly, reducing labor, material waste, and production time.

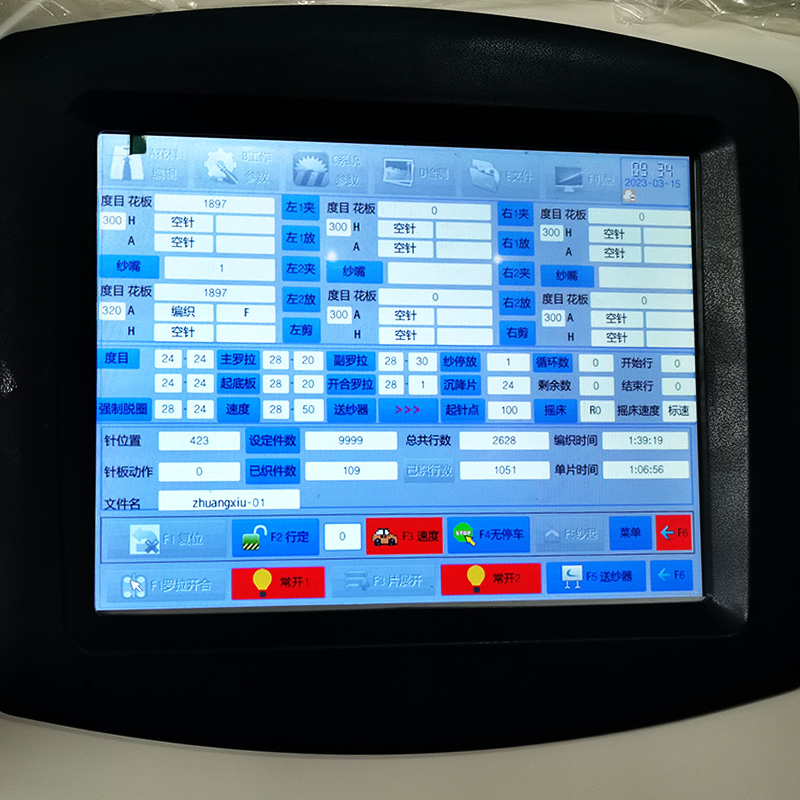

These machines use computerized controls to execute intricate designs with precision, producing sweaters, dresses, and even technical textiles without seams. The result is a garment that offers superior comfort, durability, and a perfect fit, all while minimizing environmental impact.

Key Features of Whole Garment Technology

Seamless Production: Garments are knitted in one piece, eliminating seams and reducing post-production labor.

Computerized Precision: Advanced software allows for customizable patterns and rapid design changes.

Material Efficiency: By knitting only what’s needed, these machines drastically reduce fabric waste.

Versatility: Suitable for fashion, sportswear, medical textiles, and industrial applications.

Sustainability: Supports eco-friendly production with recyclable yarns and zero-waste processes.

The Cost-Saving Potential of Whole Garment Flat Knitting Machines

Whole garment flat knitting machines address the core challenges of sweater production by optimizing resource use, reducing labor costs, and enabling on-demand manufacturing. Below, we break down the key ways these machines drive cost reductions.

1. Eliminating Fabric Waste

The Problem with Traditional Knitting

Traditional sweater production involves knitting flat panels, cutting them into shapes, and sewing them together. This “cut-and-sew” method generates significant fabric waste—up to 21% of the material can be lost during cutting. Additionally, seam allowances add to material consumption, increasing costs for manufacturers.

Zero-Waste Manufacturing with Whole Garment Machines

Whole garment flat knitting machines produce garments in their final form, using only the exact amount of yarn required. This zero-waste approach minimizes raw material costs, which is especially critical when working with premium fibers like wool, cashmere, or recycled yarns. For example, brands like Son of a Tailor report reducing fabric waste to under 1% using whole garment technology.

2. Reducing Labor Costs

Labor-Intensive Traditional Methods

In conventional sweater production, sewing panels together requires skilled labor, which is both time-consuming and expensive. These labor-intensive processes contribute to higher operational costs, particularly in regions with rising wages.

Automation with Whole Garment Machines

Whole garment machines automate the entire knitting process, producing a finished sweater in as little as 30 minutes. With minimal human intervention, manufacturers can reduce labor costs by up to 40% compared to traditional flatbed knitting. This automation also allows workers to focus on higher-value tasks, such as quality control or design programming.

3. Streamlining Production Time

Faster Time-to-Market

Whole garment machines integrate design, knitting, and finishing into a single step, significantly shortening production cycles. Traditional methods can take over six months from design to market, but whole garment technology enables rapid prototyping and production, allowing brands to respond quickly to market trends.

On-Demand Production

By supporting just-in-time manufacturing, whole garment machines eliminate the need for large inventory stockpiles. Brands can produce small batches or even bespoke garments based on customer orders, reducing the risk of overproduction and unsold inventory. Tailored Industry, for instance, uses whole garment machines to deliver products within two weeks of receiving orders, minimizing storage and disposal costs.

4. Enhancing Product Quality and Durability

Seamless Comfort and Longevity

Seamless sweaters produced by whole garment machines offer superior comfort and durability. Without seams, garments are less prone to wear and tear, increasing their lifespan and reducing returns due to defects. High-quality output enhances brand reputation, fostering customer loyalty and repeat purchases.

Customization for Premium Markets

Whole garment machines allow for intricate designs and tailored fits, catering to the growing demand for personalized apparel. Brands like Ministry of Supply use these machines to create custom blazers in 90 minutes, charging premium prices for unique, high-quality products. This ability to tap into luxury and bespoke markets boosts profitability.

5. Supporting Sustainable Production Trends

Meeting Consumer Demand for Eco-Friendly Fashion

Sustainability is no longer optional—consumers increasingly prioritize eco-friendly products. Whole garment machines align with this trend by reducing waste, energy consumption, and emissions. For example, Shima Seiki’s machines use recyclable yarns, and their Blueknit initiative allows consumers to return used garments for recycling.

Compliance with Environmental Regulations

As governments impose stricter environmental standards, such as those in Europe and North America, manufacturers face pressure to adopt sustainable practices. Whole garment machines help businesses comply with these regulations, avoiding costly penalties and enhancing market competitiveness.

Applications of Whole Garment Flat Knitting Machines

Whole garment technology extends beyond sweaters, offering versatile applications across multiple industries. Below are some key sectors where these machines excel.

Fashion and Apparel

Whole garment machines are ideal for producing high-end sweaters, dresses, and outerwear. Their ability to create complex patterns and seamless designs makes them a favorite among luxury brands and fast-fashion companies alike.

Sportswear and Performance Wear

The flexibility and breathability of seamless garments make them perfect for athletic apparel. Whole garment machines can produce compression garments and jerseys with targeted stretch zones, enhancing athlete comfort and performance.

Medical Textiles

In healthcare, whole garment machines create custom-fit medical garments, such as compression socks and orthopedic supports, tailored to individual patient needs. The use of functional yarns, like those with antimicrobial properties, further enhances their utility.

Technical Textiles

From car seat covers to industrial mesh, whole garment machines produce durable, seamless technical textiles with minimal waste. Their ability to handle specialized materials like carbon fiber and metal threads expands their industrial applications.

Why Choose Changhua's Whole Garment Flat Knitting Machines?

When it comes to whole garment flat knitting machines,

Changhua stands out as a trusted manufacturer with over 20 years of expertise. Based in China, Changhua combines cutting-edge technology, sustainability, and exceptional customer support to meet the needs of global clothing enterprises.

Changhua's Competitive Advantages

Advanced Technology for Cost Efficiency

Changhua's whole garment machines feature state-of-the-art computerized controls, high-speed capabilities, and fully formed combined rollers for precise tension control. These innovations ensure efficient production, reduced energy consumption, and minimal waste.

Sustainability at the Core

Changhua is committed to eco-friendly manufacturing, supporting the use of cotton, wool, polyester, spandex, and recycled fibers. Their machines enable zero-waste production, aligning with the circular economy and helping brands meet sustainability goals.

Global Reach and Reliable Support

With a client base spanning Europe, USA, and Asia, Changhua offers comprehensive after-sales services, including installation, training, and 24/7 technical support. Their average delivery time of 15-30 days ensures minimal downtime for manufacturers.

Customization and Flexibility

Changhua’s machines support on-demand and bespoke production, allowing brands to create tailored garments with intricate designs. This flexibility caters to both small-batch runs and large-scale orders, maximizing profitability.

Proven Durability and Longevity

Built with high-quality components, Changhua's machines are designed for long-lasting stability. Automatic oiling systems reduce wear and tear, extending the machine’s lifespan and lowering maintenance costs.

Implementing Whole Garment Machines for Cost Control

To maximize the cost-saving potential of whole garment flat knitting machines, clothing enterprises should adopt a strategic approach. Here are practical steps to ensure successful integration:

1. Invest in Operator Training

Proper training is essential for operating and programming whole garment machines. Changhua offers on-site and online training to ensure smooth operations and consistent quality.

2. Optimize Material Selection

Choose high-quality yarns compatible with whole garment machines to enhance garment quality and machine performance. Recycled and eco-friendly fibers can further reduce costs and appeal to sustainability-conscious consumers.

3. Leverage Design Software

Use advanced design systems, like Changhua’s programming software, to create virtual samples and reduce prototyping costs. Virtual simulations streamline the design process and minimize material waste.

4. Adopt Lean Manufacturing Practices

Combine whole garment technology with lean tools like Value Stream Mapping (VSM) and Single-Minute Exchange of Die (SMED) to further optimize production efficiency and reduce waste.

5. Monitor Market Trends

Stay agile by using whole garment machines for on-demand production, allowing your brand to quickly adapt to changing consumer preferences and minimize inventory risks.

The Future of Sweater Production: Sustainable and Cost-Effective

As the textile industry evolves, whole garment flat knitting machines are poised to lead the way in sustainable, cost-effective manufacturing. By eliminating waste, reducing labor costs, and enabling on-demand production, these machines empower clothing enterprises to stay competitive in a rapidly changing market.

Emerging Trends in Whole Garment Technology

4D and 5D Knitting: Future advancements will integrate sensors and adaptive fabrics into garments, expanding applications in smart textiles.

Industry 4.0 Integration: Automation and IoT connectivity will further enhance production efficiency and traceability.

Mass Customization: Growing consumer demand for personalized apparel will drive the adoption of whole garment machines for bespoke production.

Changhua's Role in Shaping the Future

With a focus on R&D and sustainability, Changhua is at the forefront of knitting technology innovation. Our whole garment machines are designed to meet the evolving needs of clothing enterprises, offering unmatched efficiency, flexibility, and eco-friendly performance.

Conclusion

Whole garment flat knitting machines are transforming sweater production by delivering significant cost savings, zero-waste manufacturing, and sustainable practices. For clothing enterprises seeking to control costs and align with consumer demand for eco-friendly fashion, these machines are a strategic investment. Changhua's whole garment flat knitting machines combine advanced technology, global support, and a commitment to sustainability, making them the ideal choice for modern manufacturers.

Ready to revolutionize your sweater production? Contact Changhua today to explore  our range of flat knitting machines.pdf and unlock the benefits of zero-waste, cost-effective manufacturing.

our range of flat knitting machines.pdf and unlock the benefits of zero-waste, cost-effective manufacturing.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe