In the fast-paced world of textile manufacturing, the 2025 flat bed knitting machine stands out as a game-changer, blending cutting-edge technology with unparalleled efficiency. If you’re a garment producer, designer, or factory owner searching for ways to boost output while minimizing waste, you’ve landed in the right place. These machines aren’t just tools—they’re the backbone of modern knitwear production, enabling everything from intricate sweaters to seamless shoe uppers. As we dive into this comprehensive guide, we’ll explore the essentials of flat bed knitting machines, their evolution, and why 2025 models are poised to dominate the industry. Whether you’re upgrading your setup or starting fresh, understanding these innovations can save you time, money, and headaches.

Flat bed knitting machines, often called computerized flat knitting machines, operate on a horizontal needle bed, allowing for precise control over stitch patterns, shapes, and textures. Unlike circular knitting machines that produce tubes of fabric, flat beds excel at creating shaped pieces directly, reducing post-production labor. In 2025, with sustainability demands rising and e-commerce driving custom orders, these machines are more relevant than ever. Imagine producing a full sweater in one seamless piece— that’s the promise of today’s flat bed knitting machine.

What is a Flat Bed Knitting Machine and How Does It Work?

At its core, a flat bed knitting machine uses two parallel needle beds (front and back) to interlock yarns into fabric. Needles move vertically to form loops, while carriages traverse the bed, selecting stitches for knitting, tucking, or transferring. Computerized versions, like those dominating 2025 models, integrate servo motors, touchscreens, and AI-driven software for pattern design and execution.

For beginners in textile production, think of it as a digital loom on steroids. Yarns are fed from creels, tensioned precisely, and woven into shapes via commands from a user-friendly interface. Key functions include:

Knitting: Basic loop formation for plain fabrics.

Tuck and Miss: Creating textures or holes.

Transfer: Moving stitches between beds for shaping collars or hems.

Jacquard and Intarsia: Multi-color patterns without floats.

These capabilities make 2025 flat bed knitting machines ideal for wool, cotton, synthetics, and blends. Production speeds can hit 1.6 meters per second, with gauges from 5G (coarse) to 18G (fine). But what sets 2025 apart? Enhanced AI for predictive maintenance and energy efficiency, addressing the industry’s push toward green manufacturing.

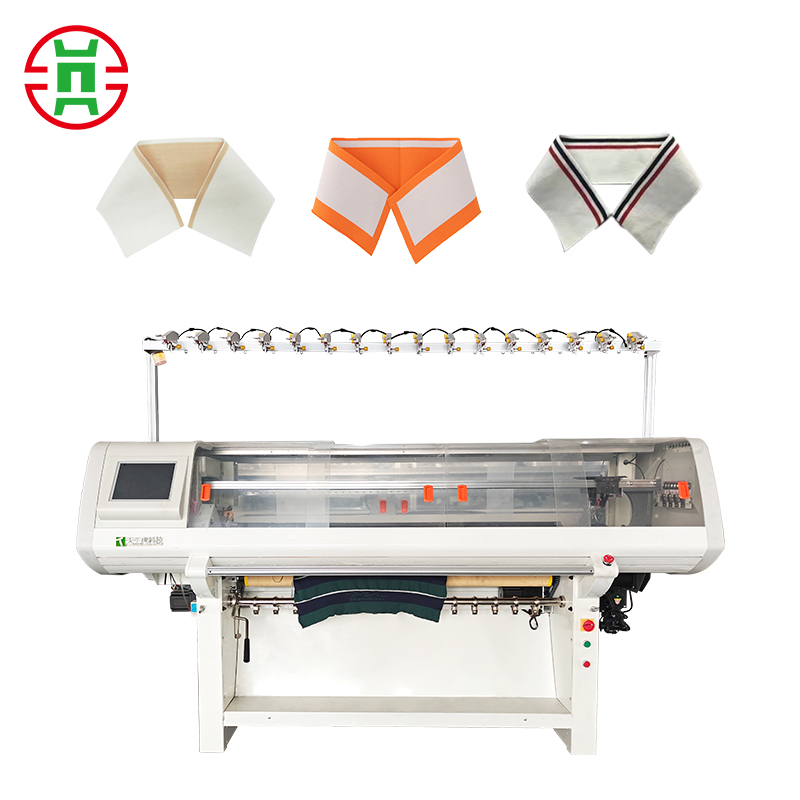

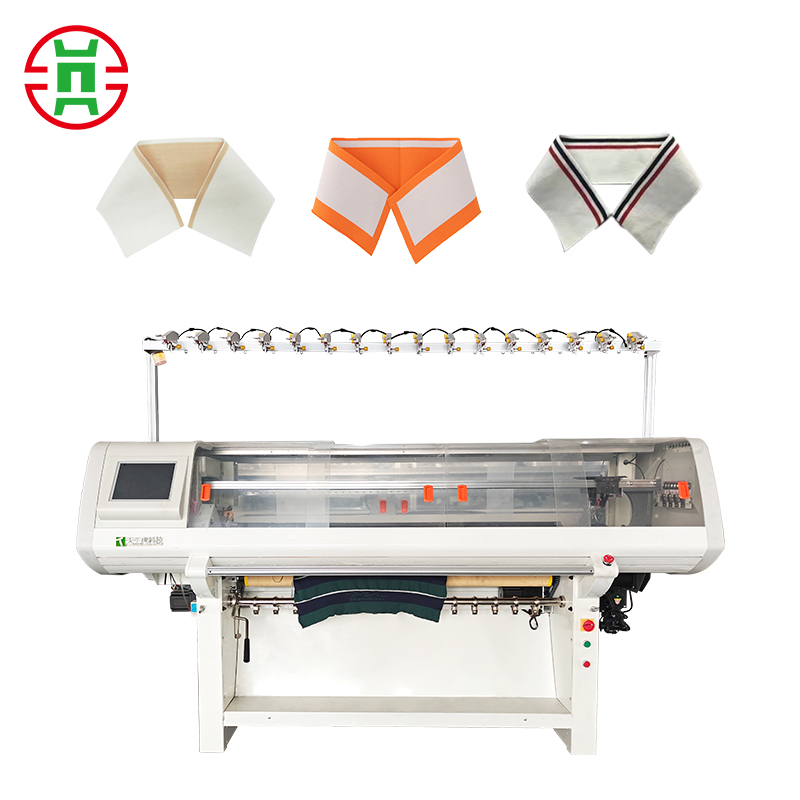

If you’re curious about real-world applications, watch this demo video of a similar machine in operation: Collar Weaving Computer Flat Knitting Machine Demonstration. It highlights the seamless workflow that could transform your workshop.

The Evolution of Flat Bed Knitting Machines: From Manual to 2025 Smart Tech

The journey of flat bed knitting machines dates back to the 19th century, when William Cotton patented the first powered version in 1864. Early models were mechanical beasts, relying on cams and levers for patterns—labor-intensive and error-prone. By the mid-20th century, Stoll and Shima Seiki introduced electronic controls, paving the way for computerized flat knitting in the 1980s.

Fast-forward to the 2000s: Multi-system carriages (double, triple) emerged, allowing simultaneous knitting on multiple sections. Today, in 2025, we’re witnessing a leap with Changhua computerized flat knitting machines integrating IoT for remote monitoring and 3D simulation software. These evolutions have slashed production times by 70% and waste by 40%, per industry reports.

Consider the shift: Manual machines produced 10-20 pieces daily; 2025 models crank out 800+. This isn’t hype—it’s driven by servo-driven racking (up to 2 inches) and dynamic stitch control via stepping motors. For historical context, early adopters like European sweater mills revolutionized fast fashion, a trend echoing in Asia’s booming textile hubs.

Key Trends Shaping 2025 Flat Bed Knitting Machines

2025 isn’t just another year—it’s a tipping point for textile tech. With global supply chains strained and consumers demanding eco-friendly apparel, flat bed knitting machines are evolving rapidly. Top trends include:

Sustainability at the Forefront

Energy-efficient models reduce consumption by 55%, using regenerative braking in motors. Recyclable yarns and zero-waste shaping minimize scraps, aligning with EU Green Deal mandates.

AI and Automation Integration

Predictive algorithms optimize paths, cutting yarn use by 15%. Expect 21-inch 4K touchscreens with 3D previews, making design intuitive even for novices.

Wider Widths for High-Volume Production

From 52-inch standards to 120-inch behemoths, wider beds knit multiple garments simultaneously—perfect for industrial parks.

Customization for Niche Markets

Intarsia for logos, pointelle for lace—2025 machines handle irregular patterns effortlessly, fueling athleisure and personalized wear.

Market forecasts predict a 6.5% CAGR for computerized flat knitting through 2030, driven by Asia-Pacific growth. If you’re eyeing expansion, now’s the time to invest.

Why 2025 is the Perfect Time to Upgrade Your Flat Bed Knitting Setup

Upgrading to a 2025 flat bed knitting machine isn’t optional—it’s essential. Labor costs are rising, and manual errors plague traditional lines. New models offer 5,000-hour uptime, with auto-lubrication extending life by 30%. Plus, with post-pandemic e-commerce booming, faster turnaround means capturing more orders.

Imagine: A single machine equaling a 10-worker team’s output. ROI? Often within 12 months, thanks to 150% efficiency gains. But not all machines are equal—choose wisely to avoid downtime pitfalls.

Introducing Changhua: Pioneers in 2025 Flat Bed Knitting Innovation

When it comes to reliable, high-performance flat bed knitting machines, few names resonate like Changhua. As a leading manufacturer, Changhua Smart Manufacturing Technology Co., Ltd. (often referred to as 昌华 in Chinese markets) has been at the forefront for over 20 years. Based in the textile heartland of Jiangsu, China, our 50,000 sqm facility produces 3,000+ units annually, exported to 30+ countries.

What sets us apart? Independent R&D with 80+ patents, including 15 inventions in servo controls and AI optimization. Our 昌华电脑横机 lineup covers single to multi-system configs, from 36 to 120 inches. Visit our official site at https://www.changhua-knitting-machine.com/ to explore our full range—we’re committed to empowering your production dreams.

At Changhua, we don’t just build machines; we build partnerships. Our 7-year warranty, 24/7 support, and ERP integration ensure seamless scaling. Ready to see how our tech fits your needs? Let’s connect. 0 “Our Changhua factory in action, producing state-of-the-art flat bed knitting machines.” “RIGHT” “SMALL”

Our Flagship: 80 Inch 1+1 System Computerized Sweater Flat Knitting Machine

For high-volume sweater production, our 80 Inch 1+1 System stands tall. Launched in 2024 and refined for 2025, this beast features an ultra-wide 80-inch (203 cm) bed, knitting four sweaters at once for 800+ daily output. The “1+1” setup divides labor: main system for basics, auxiliary for patterns like jacquard or intarsia.

Key specs:

Gauge: 5/5, 7G, 8G, 9G, 10G, 12G, 14G

Speed: Servo-controlled, up to 1.6 m/s with 32 sections

Functions: Knit, tuck, transfer, pointelle, shaping (apparent/hidden)

Yarn Compatibility: Wool, cashmere, cotton, silk blends

Dimensions/Weight: 3000x900x1700mm, 900kg

Powered by our seventh-gen AI system and 21-inch 4K touchscreen, it simulates 3D knits and optimizes paths, saving 15% yarn. Energy use? 55% lower than competitors, with noise under 52dB. Ideal for blankets, scarves, gloves too.

Dive deeper on our product page: 80 Inch 1+1 System Computerized Sweater Flat Knitting Machine. This machine disrupted our industry, boosting efficiency threefold. One client in Vietnam scaled from 200 to 1,200 pieces daily. Intrigued? Our team can demo it virtually.

Versatile Excellence: 68 Inch Double System Collar Knitting Machine

Collars demand precision—our 68 Inch Double System delivers. Tailored for shirt and jacket collars, this 2025 model uses dual carriages for simultaneous front/back knitting, ensuring flawless shapes. Gauge options up to 14G handle fine cottons to chunky wools.

Highlights:

Width: 68 inches for multiple collars per run

Systems: Double carriage for tuck/transfer synergy

Speed: 1.4 m/s max, with dynamic sinker control

Extras: Auto-tension yarn feeders, infrared take-down

It supports pointelle edges and jacquard stripes, reducing sewing time by 80%. Our stepping motor stitch density (0-650) guarantees uniformity.

Explore more: 68 Inch Double System Collar Knitting Machine. Bangladeshi factories love it for polo production; one reported 40% cost savings. If collars are your bottleneck, this could be your fix.

High-Performance Powerhouse: 72 Inch Three System Shoe Upper Knitting Machine

Shoe uppers require flexibility—our 72 Inch Three System shines here. With triple carriages, it knits complex 3D shapes for sneakers and boots, from breathable meshes to reinforced heels. 2025 updates include enhanced transfer cams for seamless seams.

Standout features:

Gauge: 7G-12G for sporty fabrics

Functions: Full jacquard, intarsia, hidden shaping

Racking: 2-inch servo for curved forms

Yarn Storage: For 12G+ gauges, ensuring tension

It handles synthetics and blends flawlessly, with 32-section speed control. Noise? Whisper-quiet at 50dB.

Check it out: 72 Inch Three System Shoe Upper Knitting Machine. Turkish footwear brands use it to prototype faster, cutting lead times in half. Footwear your focus? We’d love to customize one for you.

Unmatched Advantages of Our Changhua Flat Bed Knitting Machines

Why choose our Changhua over the rest? It’s simple: We prioritize what matters—efficiency, reliability, and support. Here’s a breakdown:

| Advantage | Description | Benefit |

| Ultra-Wide Efficiency | 80-120 inch beds knit multiples simultaneously | 3x production, ideal for factories |

| AI Optimization | Deep learning for path/yarn savings | 15% less waste, lower costs |

| Stability | Aerospace-grade rails, 5,000-hour runs | Minimal downtime, max uptime |

| Eco-Friendly | 55% energy reduction, low noise | Sustainable ops, compliant with regs |

| Versatile Functions | Jacquard, intarsia, shaping in one | Fewer machines, more creativity |

| Global Support | 1-year warranty, 48-hour service | Peace of mind worldwide |

Our machines support multi-languages (English, Spanish, Russian) and USB/ERP connectivity. No wonder we’re the go-to for 10,000-person plants.

For a visual tour, embed this factory video: Changhua Factory Overview (adapted from our channel).

How to Select the Ideal 2025 Flat Bed Knitting Machine for Your Needs

Choosing a flat bed knitting machine? Start with volume: High? Go wide like our 80 Inch. Niche? Opt for specialized like collars or uppers. Budget for gauges matching your yarns, and prioritize servo speeds for quality.

Factors:

Space/Footprint: Our models fit 3x1.7m spaces.

Power: 220V/380V compatible.

Scalability: Network-ready for fleets.

Test via our free consultation— we’ll match specs to your workflow.

Maintenance Tips for Longevity in 2025 Models

Keep your machine humming: Weekly auto-lube, monthly needle checks, quarterly software updates. Our protection systems alert for yarn breaks or errors, preventing 90% of issues.

The Future: Beyond 2025 with Changhua Innovation

Looking ahead, expect VR design and fully autonomous lines. At Changhua, we’re leading with R&D in bio-yarns. Stay tuned via our blog.

Ready to Elevate Your Production? Contact Changhua Today

Transform your textile game with a 2025 flat bed knitting machine from us. Whether it’s our 80 Inch powerhouse or a custom build, we’re here to deliver. Visit https:https://www.changhua-knitting-machine.com/ for a no-obligation quote. Your efficient future starts now—what’s your first project?

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe