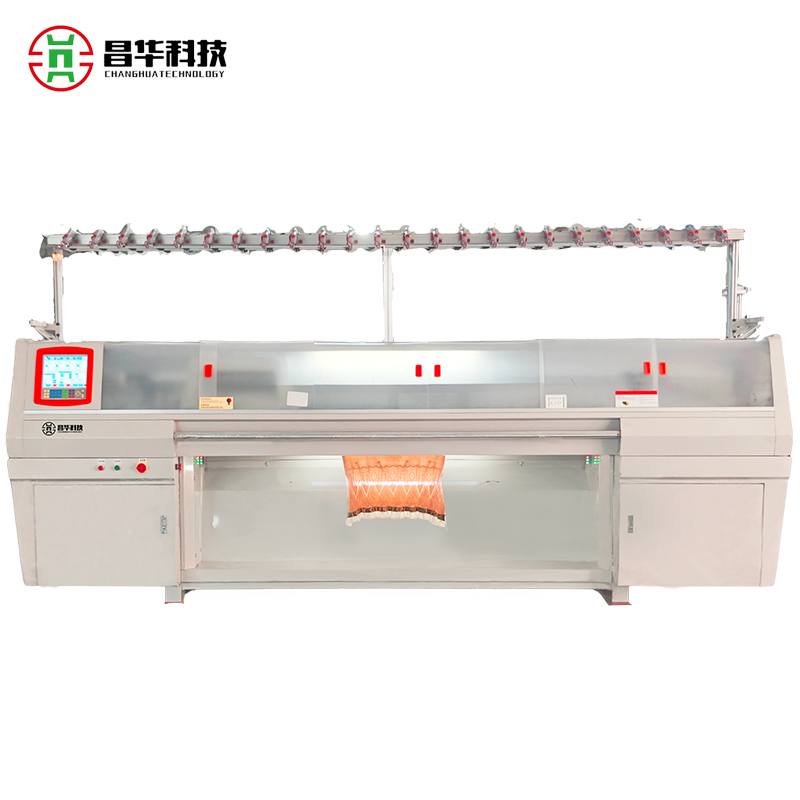

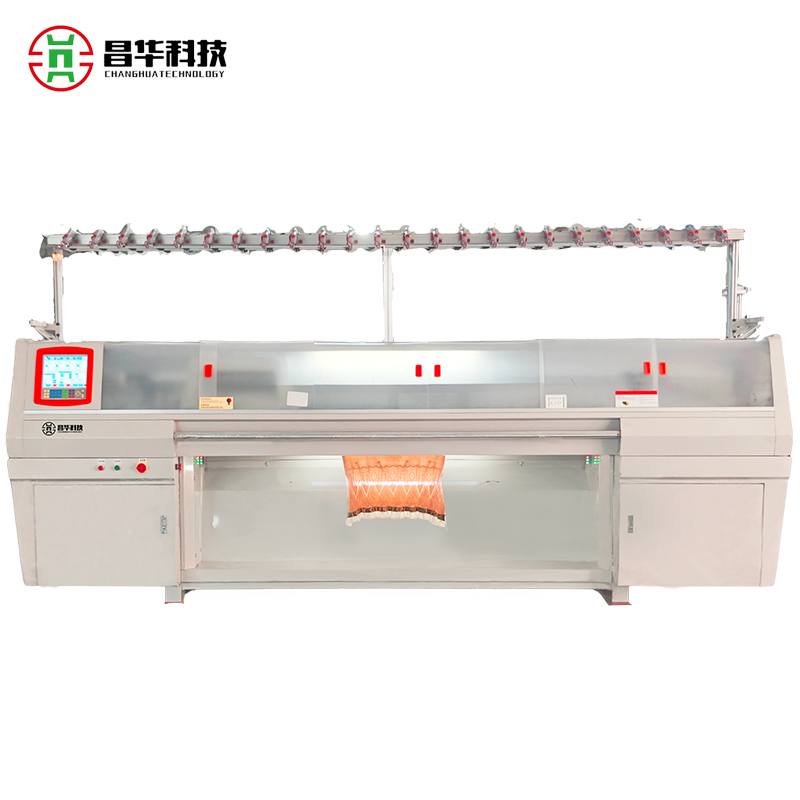

80 Inch Four System Sweater Knitting Machine Description

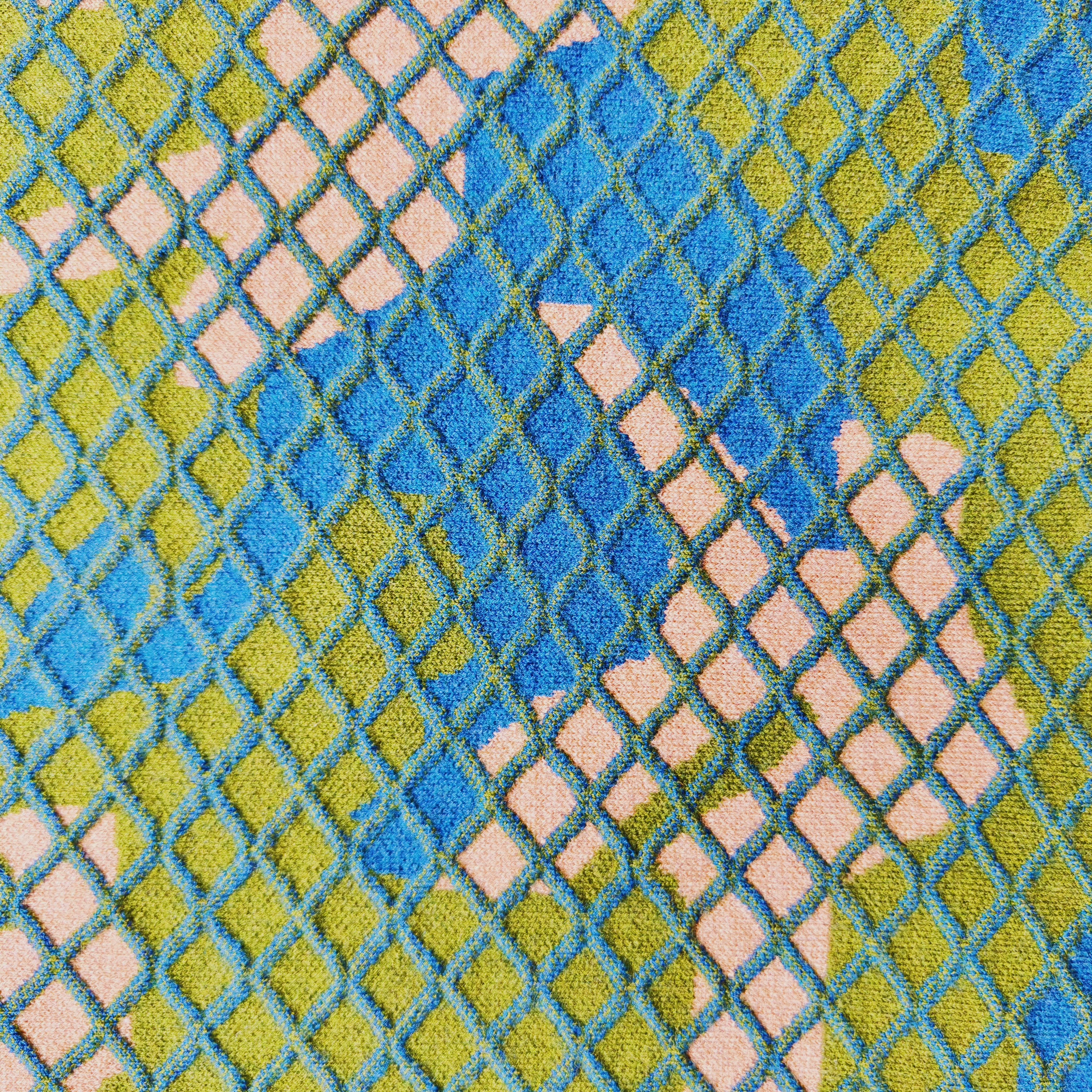

Four system has high roller, high-performance sinker, dynamic stitch, motor control reserving carriage, digital technology, high-speed and efficient, to achieve pointelle, tuck, jacquard, intarsia, full needle jacquard, apparent shape, hidden shape, and other irregular patterns, which is suitable for wool, cashmere, cotton, chemical fiber, silk and all kinds of blended yarn, the production of sweaters, blanket, scarfs, gloves, hats and knitted apparel accessories.

Exceptional Performance Core: Four-System Driven Powerful Performance

The Changhua 80-inch luxury fully automatic computerized flat knitting machine features an industry-leading four-system high-precision knitting head. This means that four knitting systems can work together efficiently, enabling the simultaneous execution of complex movements. When knitting high-end patterns such as multi-color jacquard, three-dimensional cable knit, and intarsia, it provides significantly more power and speed than dual-system machines, significantly improving knitting efficiency and the precision of pattern realization.

Luxury Configuration and Intelligent Control

This machine boasts a modern and ideal knitting width of approximately 203 centimeters (80 inches), achieving the best balance between efficient production and flexible adaptability. It integrates a luxury-grade hardware configuration and a fully computerized intelligent control system, coupled with a highly stable frame, ensuring accuracy and reliability under long-term high-load operation. The intuitive operating interface allows for easy import and editing of complex pattern programs, enabling fully automatic intelligent production.

Positioned for High-End Manufacturing and Premium Production

This model is positioned to serve high-end knitting manufacturing enterprises with extremely high demands for quality, efficiency, and complex processes. It is the ideal choice for producing luxury yarn products (such as cashmere and silk), high-end fashion knitwear, and premium home textiles, helping enterprises secure high-value orders, build core competitiveness, and is a strategic equipment investment for entering the high-end market.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe