Knitting blankets by hand is a labor of love, but it's time-consuming and physically demanding. For hobbyists, small business owners, or manufacturers looking to produce high-quality blankets efficiently, a knitting machine is a game-changer. These machines streamline the process, allowing you to create soft, cozy blankets with intricate patterns in a fraction of the time. But where do you buy a knitting machine for blankets, and how do you choose the right one? This comprehensive guide explores the world of knitting machines, their applications, and why Changhua's cutting-edge technology stands out as a top choice.

Whether you're a beginner knitter, a craft enthusiast, or a factory owner scaling up production, this article will help you navigate the options available, with a focus on finding the perfect machine for crafting beautiful blankets. Let's dive into the mechanics, applications, and where to source the best knitting machines, including a spotlight on Changhua's industry-leading solutions.

Understanding Knitting Machines for Blankets

Knitting machines are specialized devices that automate the process of creating knitted fabrics. Unlike hand knitting, which relies on needles and manual effort, knitting machines use a series of needles on a flatbed or circular frame to produce rows of stitches quickly and consistently. For blankets, flatbed knitting machines are particularly popular because they create wide, flat panels ideal for throws, afghans, and bedspreads.

Types of Knitting Machines

Flatbed Knitting Machines

Flatbed machines are the go-to choice for blanket production. They feature a horizontal needle bed where needles move back and forth to create flat fabric panels. These machines are versatile, capable of handling various yarn weights and producing complex patterns like jacquard, ribbing, or textured stitches.

Circular Knitting Machines

Circular machines produce tubular fabrics, which are better suited for items like socks or hats. While some models can be adapted for flat panels, they're less common for blankets due to limitations in width and pattern versatility.

Computerized vs. Manual Machines

Computerized flat knitting machines, like those offered by Changhua, use digital technology to automate tasks such as yarn feed, stitch formation, and pattern changes. Manual machines require more hands-on input but are often more affordable for beginners.

Applications of Knitting Machines for Blankets

Knitting machines are used across various sectors, from home crafting to industrial manufacturing. Here's how they're applied:

Home Crafting

Hobbyists use knitting machines to create custom blankets for personal use or small-scale sales. Machines like the Silver Reed LK150 or Addi Express Kingsize are popular for their ease of use.

Small Businesses

Etsy sellers and boutique crafters rely on mid-gauge or computerized machines to produce blankets with unique designs, catering to niche markets.

Industrial Manufacturing

Factories use high-capacity computerized flat knitting machines to mass-produce blankets for retail, hospitality, or healthcare sectors.

Charity and Community Projects

Knitters creating blankets for hospitals, hospices, or shelters benefit from machines that speed up production, allowing them to donate more items.

Blankets made with knitting machines can range from simple stockinette stitch throws to intricate jacquard designs, offering endless creative possibilities. The key is choosing a machine that matches your production needs and skill level.

Where to Buy a Knitting Machine for Blankets Factory Options

When it comes to purchasing a knitting machine for blankets, factory-direct options offer the best value, especially for businesses or serious crafters. Buying from a manufacturer ensures access to the latest technology, customization options, and wholesale pricing. Below, we explore factory options, with a special focus on Changhua, a leading name in knitting machinery.

Why Buy from a Factory?

Quality Assurance: Factories like Changhua produce machines with rigorous quality control, ensuring durability and performance.

Customization: Manufacturers can tailor machines to specific needs, such as wider needle beds for larger blankets or specialized gauges for thick yarns.

Cost Savings: Wholesale pricing from factories reduces costs compared to retail markups.

After-Sales Support: Reputable manufacturers offer maintenance, spare parts, and technical support, crucial for long-term use.

Changhua: Your Trusted Factory for Blanket Knitting Machines

Located in Changshu, Jiangsu, Changhua Smart Manufacturing Technology Co., Ltd. has over 20 years of experience in producing high-quality knitting machines. Known for brands like “Changhua,” “Tiangong,” and “King Tiger,” the company is a global leader in flat knitting technology. Our blanket knitting machines are designed for efficiency, versatility, and precision, making them ideal for both small-scale and industrial production.

Changhua's Blanket Knitting Machine Features

Three-System Technology

Changhua's blanket knitting machines feature double, 2+2, or 3+3 systems with digital technology, enabling complex patterns like rib transfer, jacquard, and needle narrowing.

High-Speed Efficiency

Equipped with high rollers, dynamic stitch control, and motor-driven carriages, these machines maximize output while maintaining quality.

Versatile Yarn Compatibility

Suitable for wool, cashmere, cotton, silk, and blended yarns, allowing you to create blankets of varying textures and weights.

Energy Efficiency

Changhua's intelligent programming reduces energy consumption, making their machines eco-friendly and cost-effective.

Wide Needle Beds

Models like the 80-inch 16G Three-System Computerized Flat Knitting Machine accommodate large blanket widths, perfect for oversized throws.

Why Choose Changhua?

Proven Track Record

With an annual output of over 6,000 machines, Changhua's reliability is unmatched.

Global Reach

Our machines are used worldwide, with support for multiple languages and markets.

Innovation-Driven

Changhua invests in R&D to deliver cutting-edge features, such as automated tension adjustment and fast programming.

Comprehensive Support

From setup guidance to troubleshooting, Changhua's experts ensure a seamless experience.

To purchase, visit Changhua’s official website or contact Our sales team for wholesale inquiries. Our user-friendly platform offers detailed product specs, videos, and quote requests.

Recommended Changhua Models for Blankets

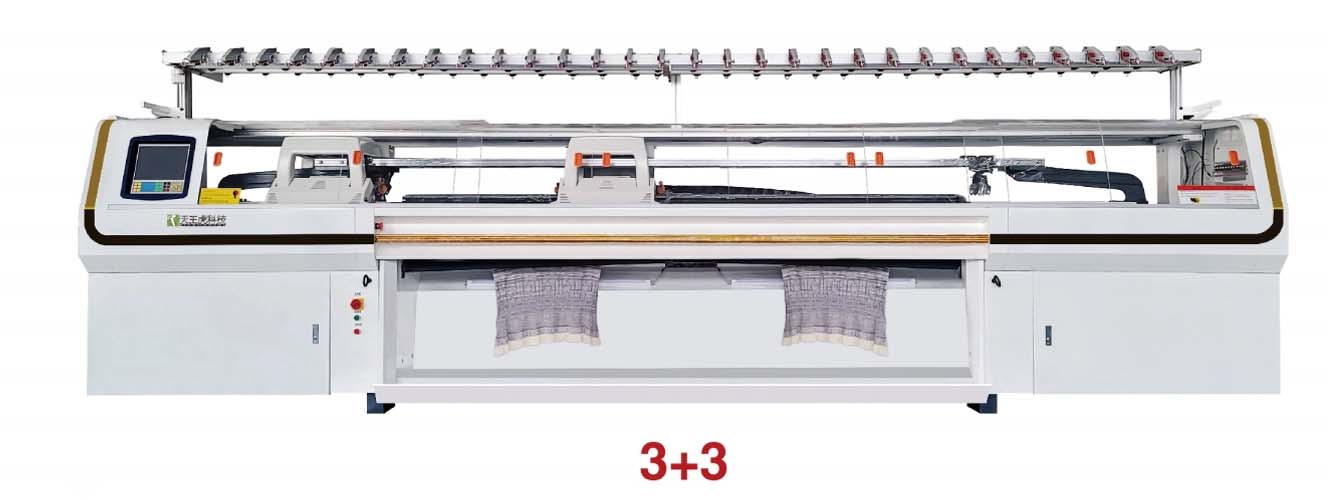

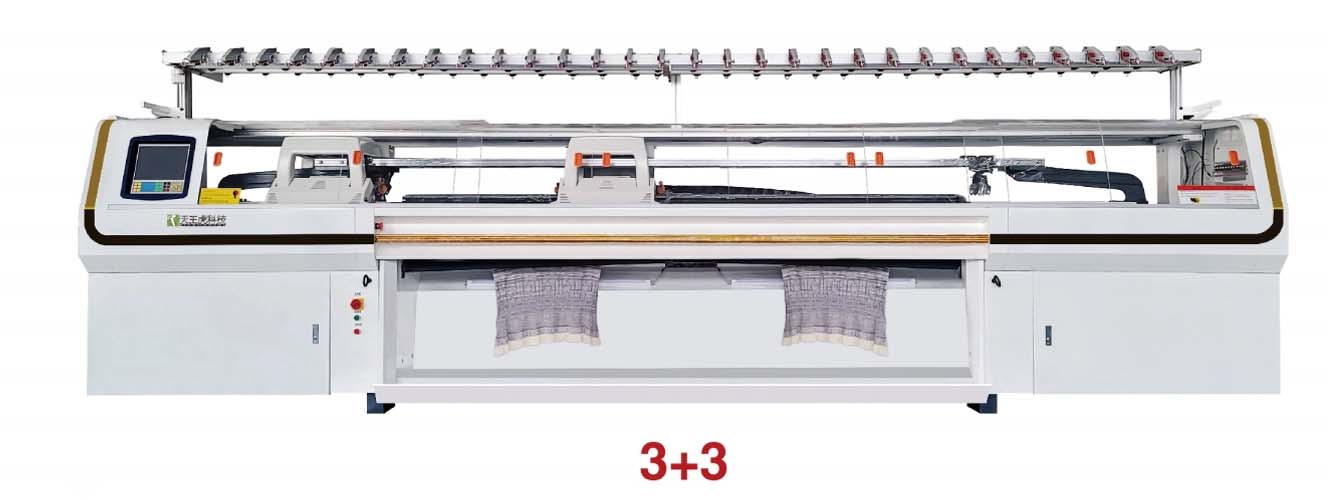

100 Inch 14G 3+3 System Computerized Blanket Flat Knitting Machine

This industrial-grade machine is a powerhouse for large-scale blanket production. With a 100-inch needle bed and advanced 3+3 system technology, it excels at creating oversized blankets, such as king-sized bedspreads or commercial throws, with intricate patterns like jacquard, rib transfer, or needle narrowing. Its digital technology, high-performance sinkers, and motor-controlled carriage enable high-speed knitting (up to 1.6m/s) and precise stitch control, ensuring consistent quality across wide panels. The machine supports a variety of yarns, including wool, cashmere, cotton, and blended fibers, making it ideal for factories producing premium blankets for retail or hospitality sectors.

This industrial-grade machine is a powerhouse for large-scale blanket production. With a 100-inch needle bed and advanced 3+3 system technology, it excels at creating oversized blankets, such as king-sized bedspreads or commercial throws, with intricate patterns like jacquard, rib transfer, or needle narrowing. Its digital technology, high-performance sinkers, and motor-controlled carriage enable high-speed knitting (up to 1.6m/s) and precise stitch control, ensuring consistent quality across wide panels. The machine supports a variety of yarns, including wool, cashmere, cotton, and blended fibers, making it ideal for factories producing premium blankets for retail or hospitality sectors.

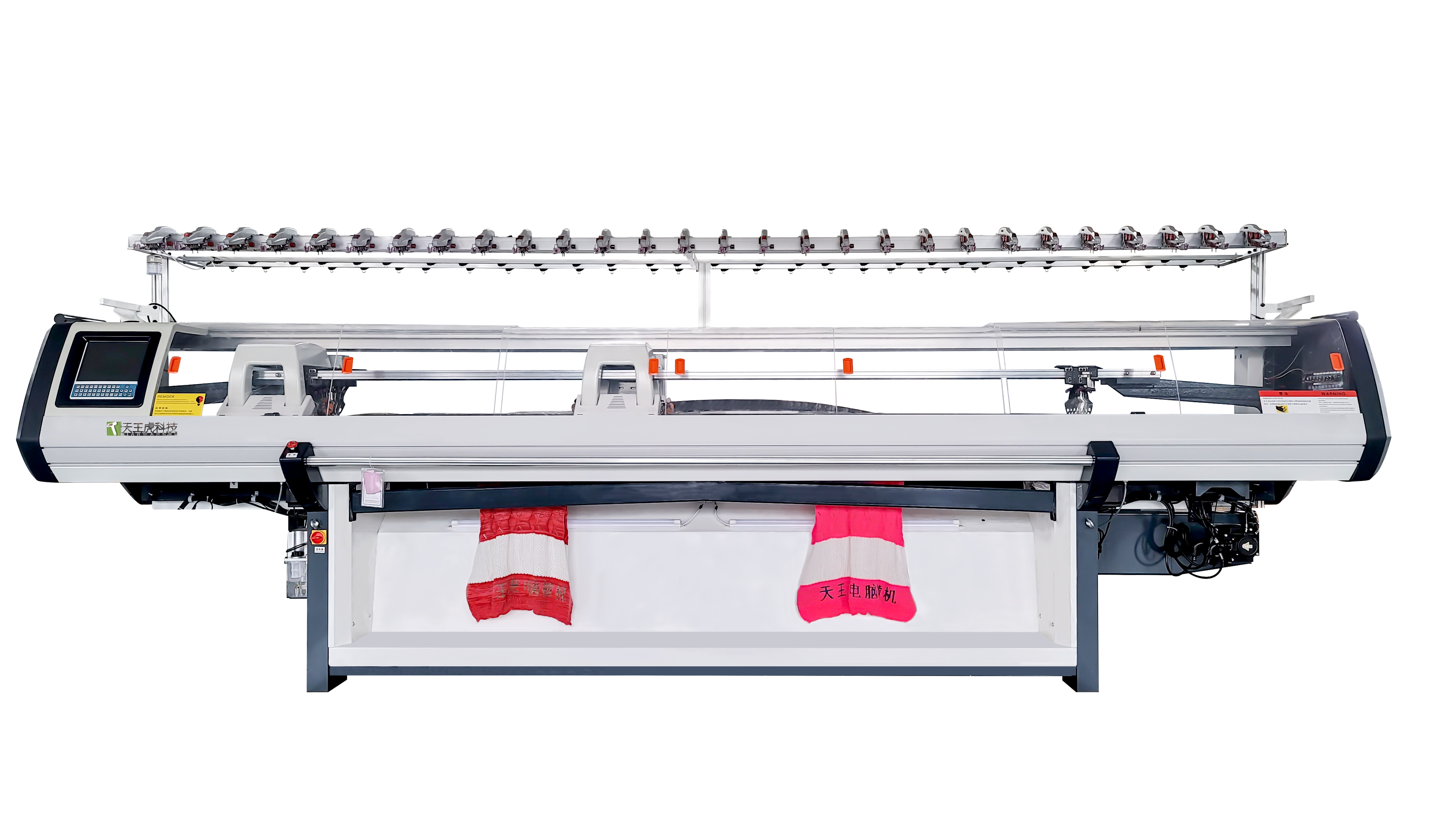

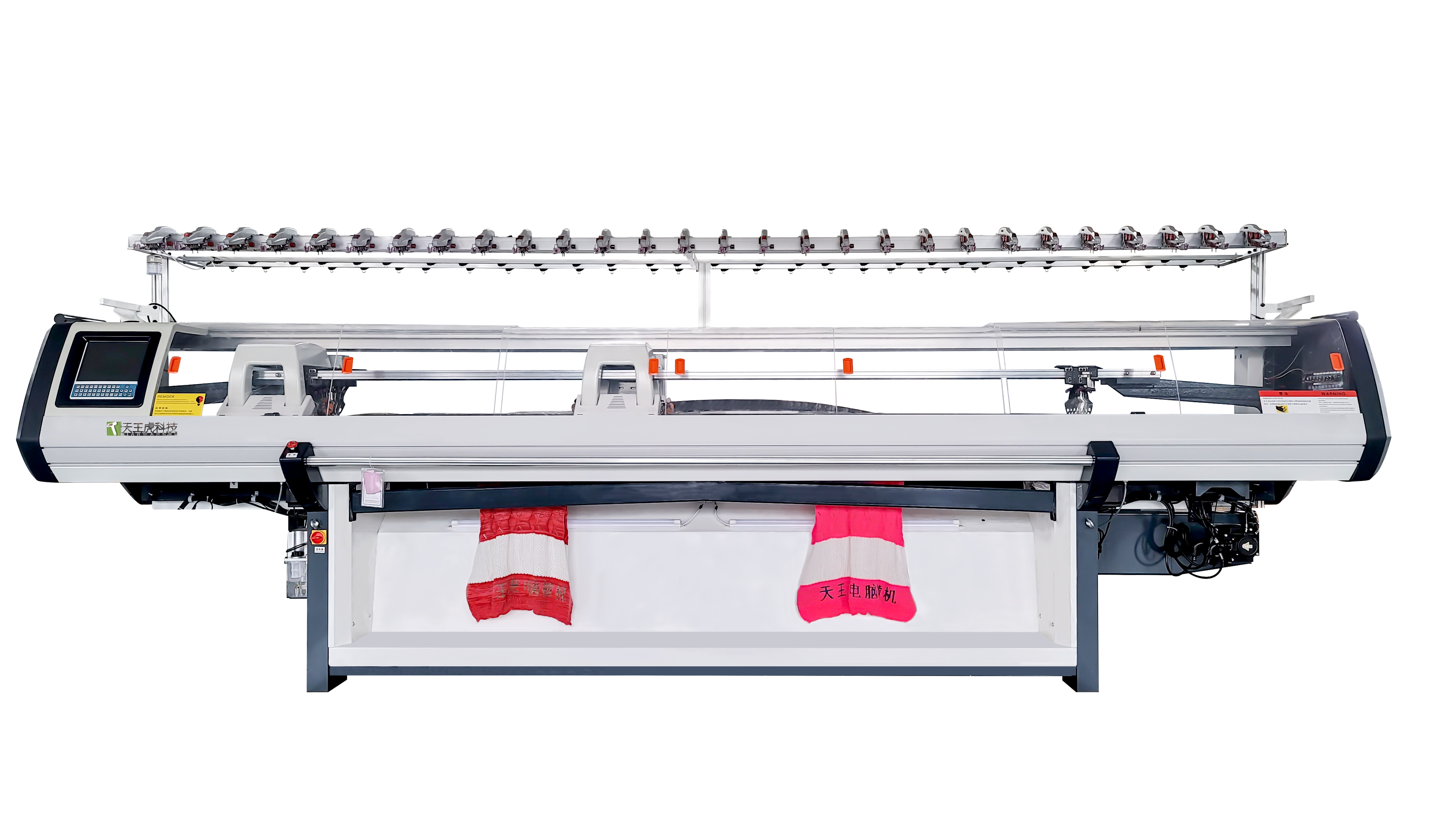

120 Inch 12G 2+2 System Computerized Flat Knitting Machine

Perfect for mid-sized manufacturers or boutique businesses, this 2+2 system machine features a 120-inch needle bed, allowing for the production of extra-wide blankets, such as oversized throws or decorative afghans. Its digital technology supports complex patterns like pointelle, tuck, intarsia, and full jacquard, offering creative flexibility for custom designs. Equipped with high rollers and dynamic stitch control, it ensures smooth operation and uniform tension, even with thicker yarns like worsted or bulky blends. This model is an excellent choice for businesses aiming to balance high output with intricate, marketable blanket designs.

80 Inch 16G Three-System Computerized Flat Knitting Machine

Designed for versatility, this three-system machine with an 80-inch needle bed is suitable for both small-scale and industrial blanket production. It's ideal for crafting medium to large blankets, such as queen-sized throws or baby blankets, with patterns ranging from simple stockinette to complex jacquard. The model features a fully formed combined roller system for precise tension control and supports yarns like cotton, wool, and synthetic blends. Its high-speed servo-motor and automated functions make it user-friendly for smaller operations while still meeting the demands of larger production runs, making it a great all-purpose choice.

For detailed specifications, demonstration videos, or to download the product guide (e.g., “ Changhua Flat Knitting Machine.pdf.pdf”), visit Changhua's blanket knitting machine page. Contact our sales team for wholesale pricing, customization options, or after-sales support to tailor these machines to your blanket production needs.

Changhua Flat Knitting Machine.pdf.pdf”), visit Changhua's blanket knitting machine page. Contact our sales team for wholesale pricing, customization options, or after-sales support to tailor these machines to your blanket production needs.

Where to Buy a Knitting Machine for Blankets: Factory Spotlight on Changhua

Changhua’s commitment to innovation and quality makes it a standout choice for blanket knitting machines. Their factory in Changshu, Jiangsu, is equipped with state-of-the-art production lines, producing over 6,000 machines annually. Here’s why Changhua is the preferred factory for blanket knitting machines:

Advanced Technology

Changhua's machines incorporate features like:

Dynamic Stitch Control: Ensures consistent stitch quality across large blanket panels.

High-Performance Sinkers: Enhance pattern accuracy for complex designs.

Automated Rollers: Control tension for seamless knitting of wide fabrics.

Sustainability Focus

The needle bed size affects the width of the fabric. For example, a 150-needle bed is suitable for smaller projects, while a 272-needle bed is ideal for larger garments.

Global Accessibility

With a multilingual website and worldwide distribution, Changhua makes it easy to purchase their machines. They offer detailed product videos, PDFs, and online support to guide buyers. Visit our website for resources like:

Product Catalog PDF:  Downloadable specs.pdf for all blanket knitting machines.

Downloadable specs.pdf for all blanket knitting machines.

Setup Videos: Step-by-step guides for beginners and professionals.

Tips for Buying a Knitting Machine for Blankets

Research Thoroughly

Compare models based on gauge, features, and reviews. Websites like yarn-store.com offer detailed guides.

Test Before Buying

If possible, try a machine through a knitting club or dealer.

Check Yarn Compatibility

Ensure the machine supports the yarn weights you plan to use.

Consider Maintenance

pt for brands with accessible spare parts, like Changhua or Silver Reed.

Budget for Accessories

Ribbers, lace carriages, or software may enhance your machine’s capabilities.

Conclusion

Finding the right knitting machine for blankets depends on your needs, whether you're a hobbyist crafting cozy throws or a factory producing blankets at scale. For unparalleled quality, versatility, and support, Changhua Smart Manufacturing Technology Co., Ltd. is the top choice. Our advanced flat knitting machines, backed by 20+ years of expertise, offer everything you need to create beautiful blankets efficiently. Visit Changhua’s website to explore our range, request a quote, or  download our product guide.pdf.

download our product guide.pdf.

For hobbyists, retail options like Amazon, eBay, or specialty stores provide accessible machines, while local dealers and knitting clubs offer hands-on support. Wherever you buy, prioritize gauge, width, and patterning capabilities to ensure your machine meets your blanket-making goals. With the right knitting machine, your creativity—and productivity—will soar.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe