In today's fast-paced manufacturing world, businesses are constantly seeking ways to balance efficiency, quality, and cost. Semi-automatic machines have emerged as a vital solution, offering a blend of automation and manual control that caters to various industries. Whether you're a small-scale textile producer or a large garment manufacturer, understanding semi-automatic machines and their applications can transform your production process. This comprehensive guide explores what semi-automatic machines are, their benefits, applications, and why our company, Changhua, is a trusted name in this field, particularly with our semi-automatic flat knitting machines.

Understanding Semi-Automatic Machines

Definition and Core Concept

A semi-automatic machine is a piece of equipment that combines automated processes with manual intervention. Unlike fully automatic machines, which operate with minimal human input, semi-automatic machines require operators to handle specific tasks, such as setting up materials, adjusting settings, or switching between operations. This hybrid approach makes them ideal for industries that need flexibility and precision without the high costs of full automation.

How Semi-Automatic Machines Work

Semi-automatic machines typically feature automated components, such as motorized needle movements or computer-controlled patterns, but rely on human operators for tasks like yarn feeding, tension adjustments, or pattern changes. This setup allows for greater control over the production process, enabling customization and adaptability while maintaining efficiency. For example, in textile manufacturing, a semi-automatic machine might automatically knit a fabric pattern but require an operator to change the yarn or adjust the needle bed.

Key Features of Semi-Automatic Machines

Hybrid Operation: Combines automated processes with manual inputs for flexibility.

Cost-Effectiveness: Lower initial investment compared to fully automatic systems.

Versatility: Capable of producing a wide range of products with varying patterns and materials.

Ease of Use: User-friendly interfaces, often with digital controls, make operation accessible to skilled workers.

Precision: Advanced technology ensures high-quality output with minimal errors.

Applications of Semi-Automatic Machines

Semi-automatic machines are used across various industries, from textiles to automotive and food processing. Their ability to balance automation and manual control makes them suitable for both small-scale and medium-scale production. Below, we explore some of the key industries where semi-automatic machines shine.

Textile and Garment Industry

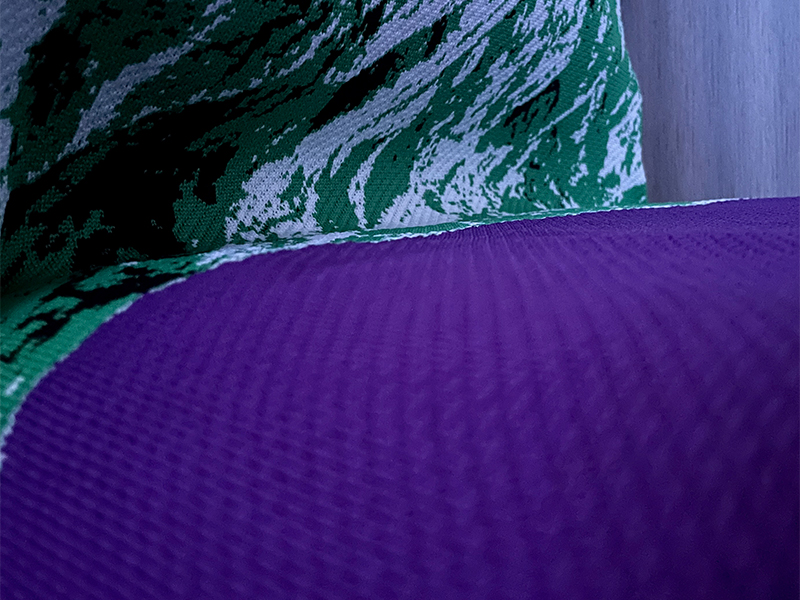

In the textile industry, semi-automatic machines are widely used for producing flat fabrics, such as sweaters, scarves, and collars. These machines excel in creating intricate patterns, such as semi-jacquard or tuck stitches, while allowing operators to customize designs on the fly. They are particularly popular among small to medium-sized businesses and designers who need to produce sample garments or small batches of specialized knitwear. The ability to use different needle sizes also enables the production of fabrics with varying thicknesses, catering to diverse market demands.

Automotive Industry

Semi-automatic machines are employed in the automotive sector for tasks like assembling components or producing interior textiles. For instance, they can be used to create custom upholstery or technical textiles with precise specifications. The manual input allows operators to adjust settings to meet the stringent quality standards of automotive manufacturing.

Food and Beverage Industry

In food processing, semi-automatic machines are used for tasks like packaging, filling, or cutting. These machines automate repetitive tasks while allowing operators to monitor quality and make adjustments as needed, ensuring compliance with safety and hygiene standards.

Benefits of Semi-Automatic Machines

Cost-Effective Production

For businesses looking to optimize costs, semi-automatic machines offer a lower upfront investment compared to fully automatic systems. They also reduce labor costs by automating repetitive tasks, allowing one operator to manage multiple machines.

Flexibility and Customization

The manual components of semi-automatic machines provide unparalleled flexibility. Operators can adjust settings, change patterns, or switch materials without the need for extensive reprogramming, making these machines ideal for custom or small-batch production.

High-Quality Output

With advanced digital technology, semi-automatic machines deliver precise and consistent results. For example, in textile production, they ensure clear fabric lines, uniform edges, and excellent flatness, addressing common issues like uneven stitches or fabric distortion.

Energy Efficiency

Modern semi-automatic machines are designed with energy-saving components, reducing operational costs and environmental impact. This makes them a sustainable choice for businesses aiming to align with eco-friendly practices.

Ease of Maintenance

Semi-automatic machines are built for durability, with features like automatic oiling systems that reduce wear and tear. Regular maintenance, such as cleaning lint or oiling moving parts, is straightforward, ensuring long-term reliability.

Why Choose Changhua's Semi-Automatic Flat Knitting Machines?

When it comes to semi-automatic machines, our company, Changhua, stands out as a leader in the textile industry. With over 20 years of experience, Changhua has built a reputation for quality, innovation, and customer satisfaction. Our semi-automatic flat knitting machine are designed to meet the needs of modern textile manufacturers. Here's why our machines are the perfect choice for your business.

About Changhua

Located in Changshu, Jiangsu, the birthplace of the apparel industry, Changshu Changhua Smart Manufacturing Technology Co., Ltd. is a professional manufacturer of knitting machinery. Our brands, including "Changhua," "Tiangong," "King Tiger," and "Miao’s Craftsman," are synonymous with quality and innovation. We are committed to advancing the modernization of the knitting industry through cutting-edge technology and a customer-centric approach.

Features of Our Semi-Automatic Flat Knitting Machines

Our semi-automatic flat knitting machinesare specially designed for knitting collars and ribs, addressing common challenges like unclear fabric lines, uneven edges, and insufficient flatness. Here are some key features:

Milling-Type Needle Bed: Ensures precision and durability, producing high-quality fabrics with clear patterns.

Digital Technology: Enables functions like knitting, semi-jacquard, A/B jack tuck, and full tuck, allowing for versatile pattern creation.

User-Friendly Interface: Operators can create designs directly on the machine’s screen, streamlining the production process.

High Precision Components: The bed-base, guide rail, needle-bed, cam-board, and cams are engineered for straightness, flatness, and accuracy.

Versatile Applications: Suitable for producing collars, clothing accessories, and other flat fabrics using materials like wool, cotton, or blended yarns.

Benefits of Choosing Changhua's Machines

Superior Quality: Our machines deliver consistent, high-quality output, ensuring your products meet market standards.

Cost-Effective: While offering advanced features, our machines are priced competitively, making them accessible to businesses of all sizes.

Global Support: With a robust after-sales service network, we provide 24/7 technical support and comprehensive training to ensure seamless operation.

Customization: Our machines support a variety of patterns, including square semi-jacquard and line designs, giving you the flexibility to meet diverse customer demands.

Sustainability: Energy-efficient components and durable construction reduce operational costs and environmental impact.

How to Choose the Right Semi-Automatic Machine

Assess Your Production Needs

Consider the type of products you plan to manufacture and the volume of production. For small to medium-sized businesses, our semi-automatic flat knitting machines are ideal for producing custom knitwear or small batches.

Evaluate Features and Technology

Look for machines with digital controls, versatile pattern capabilities, and durable components. Changhua's machines offer advanced digital technology and precision engineering, ensuring long-term reliability and flexibility.

Consider Budget and ROI

While semi-automatic machines are more affordable than fully automatic ones, it's essential to balance cost with features. Our machines provide a high return on investment by reducing labor costs and material waste.

Check After-Sales Support

Choose a manufacturer with a strong support network. Changhua offers 24/7 technical assistance, comprehensive training, and long-term parts supply to keep your machines running smoothly.

Common Challenges and Solutions

Uneven Stitches

Solution: Check needle alignment and yarn tension. Regular maintenance, such as cleaning lint and oiling moving parts, can prevent this issue.

Machine Jamming

Solution: Ensure regular cleaning and lubrication of moving parts. Our machines feature automatic oiling systems to minimize wear and tear.

Software Errors

Solution: Update firmware and reset settings as needed. Our user-friendly interface simplifies troubleshooting and maintenance.

Conclusion

Semi-automatic machines offer a perfect blend of automation and manual control, making them a valuable asset for industries like textiles, automotive, and food processing. Their flexibility, cost-effectiveness, and high-quality output make them ideal for businesses seeking to optimize production without sacrificing customization. At Changhua, our semi-automatic flat knitting machines are designed to deliver precision, versatility, and durability. With over 20 years of experience, we are proud to support businesses worldwide in achieving their production goals. Contact us today to learn how our machines can elevate your manufacturing process.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe