In the ever-evolving world of textile manufacturing, glove knitting machines have become indispensable for producing high-quality gloves used in labor protection, medical applications, and fashion. Achieving seamless connections at the fingertip area is a critical challenge for manufacturers, as it directly impacts the comfort, durability, and functionality of the gloves. This article explores the intricacies of high-precision control in glove knitting machines, focusing on seamless fingertip connections, and highlights how Changhua's advanced 13G glove knitting machines address these challenges to deliver superior results for labor protection and medical glove manufacturers.

Introduction to Glove Knitting Machines

A glove knitting machine is a specialized piece of equipment designed to automate the production of knitted gloves. Unlike traditional hand-knitting methods, these machines offer high-speed production, consistent quality, and the ability to create complex patterns with precision. Modern glove knitting machines are equipped with computerized systems that allow manufacturers to produce seamless gloves with varying gauges, sizes, and materials, catering to industries such as labor protection, medical, and fashion.

Importance of High-Precision Control

High-precision control in glove knitting machines refers to the ability to finely tune the knitting process to achieve consistent stitch quality, accurate sizing, and seamless connections, particularly in critical areas like the fingertips. This level of control is essential for:

Comfort: Seamless fingertips reduce irritation and enhance wearability, especially for prolonged use in medical or labor-intensive environments.

Durability: Precise stitching prevents weak points that could lead to tearing or fraying.

Functionality: Seamless connections ensure gloves fit snugly, improving dexterity for tasks requiring fine motor skills, such as handling tools or medical instruments.

Aesthetics: A smooth, seamless finish enhances the visual appeal of fashion gloves.

Applications of Glove Knitting Machines

Glove knitting machines are versatile, serving multiple industries:

Labor Protection: Gloves for construction, manufacturing, and industrial applications require durability and flexibility, often achieved through seamless designs.

Medical Gloves: Medical-grade gloves, such as those used in surgical or cleanroom environments, demand precision and hygiene, with seamless fingertips to prevent contamination.

Fashion and Touchscreen Gloves: The rise of touchscreen-compatible gloves has increased the need for conductive yarns and precise knitting to ensure functionality without compromising comfort.

Cold-Weather Gloves: Seamless connections in winter gloves enhance warmth and fit, improving user experience.

Challenges in Achieving Seamless Fingertip Connections

Why Seamless Fingertips Matter

The fingertip area of a glove is one of the most challenging parts to knit seamlessly. Traditional glove knitting often results in visible seams or loose stitches at the fingertips, which can cause discomfort, reduce durability, and compromise functionality. Seamless fingertips are particularly important for:

Medical Gloves: Seams can harbor bacteria or compromise sterility.

Labor Protection: Seams at the fingertips can wear out quickly under heavy use, leading to glove failure.

Touchscreen Gloves: Conductive yarns must be precisely integrated into the fingertip area to ensure consistent touchscreen functionality.

Common Pain Points in Glove Manufacturing

Manufacturers face several challenges when striving for seamless fingertip connections:

Stitch Precision: Inconsistent stitch density can lead to gaps or weak points at the fingertips.

Yarn Management: Improper handling of yarns, especially conductive or specialty yarns, can result in uneven knitting.

Machine Calibration: Older machines may lack the precision needed for seamless connections, leading to manual finishing processes that increase labor costs.

Material Compatibility: Different materials (e.g., cotton, polyester, Kevlar, or conductive yarns) require specific machine settings to achieve seamless results.

Production Efficiency: Balancing speed and precision is critical to meet high-volume demands without sacrificing quality.

High-Precision Control in Glove Knitting Machines

Advanced Computerized Control Systems

Modern glove knitting machines, such as those offered by Changhua, utilize advanced computerized control systems to achieve high-precision knitting. These systems allow manufacturers to:

Program Stitch Patterns: Precise control over stitch density and tension ensures consistent knitting across the glove, including the fingertip area.

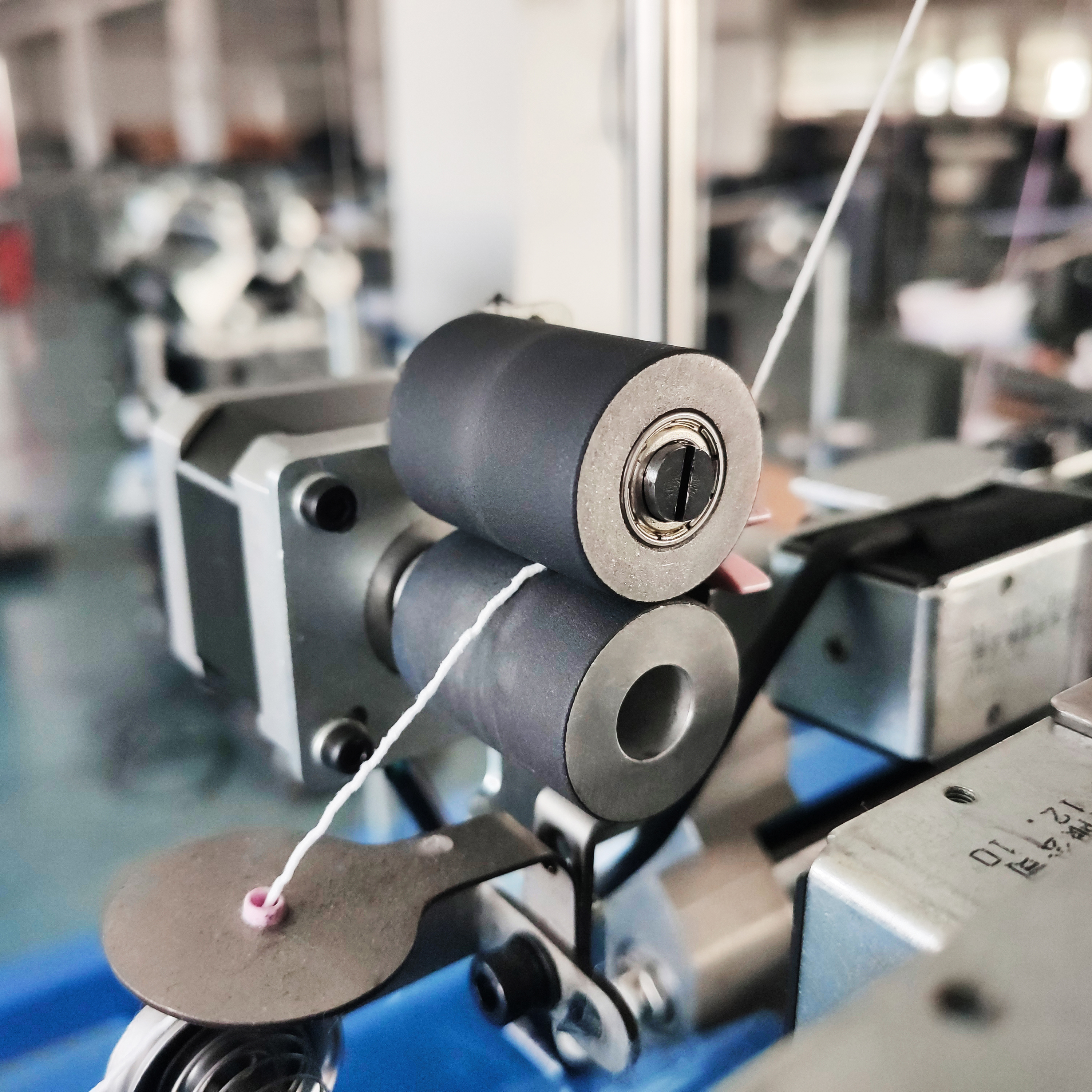

Automate Yarn Feeding: Automated yarn management prevents loose or uneven stitches, critical for seamless connections.

Monitor Real-Time Performance: Sensors and digital interfaces provide real-time feedback, allowing operators to adjust settings instantly to maintain quality.

Sinker Knitting Systems

The sinker knitting system is a key feature in achieving seamless fingertips. This system enhances the elasticity and toughness of the knitted fabric, ensuring that the glove conforms to the hand’s shape without visible seams. By using high-precision sinkers, manufacturers can produce gloves with:

Improved Stretch: Ensures a snug fit at the fingertips.

Enhanced Durability: Reduces wear and tear at stress points.

Better Hand Feel: Provides a smooth, comfortable experience for the wearer.

High-Gauge Knitting for Precision

High-gauge machines, such as 13G or 18G, are ideal for producing gloves with fine, tight stitches that mimic the feel of bare hands. These machines are particularly effective for seamless fingertip connections, as they allow for:

Tighter Stitches: Minimize gaps and ensure a smooth finish.

Fine Yarn Compatibility: Work with thinner yarns, such as those used in medical or touchscreen gloves.

Customizable Patterns: Enable intricate designs without compromising seam quality.

Automatic Overlock Devices

Traditional glove knitting often requires manual overlocking to finish seams, which is time-consuming and labor-intensive. Modern machines incorporate automatic overlock devices that eliminate the need for manual finishing, ensuring seamless fingertips while reducing production costs.

Centralized Lubrication Systems

High-precision machines require consistent maintenance to maintain performance. Centralized lubrication systems automatically supply oil to critical components, reducing wear and ensuring smooth operation. This contributes to consistent knitting quality, particularly in the delicate fingertip area.

Changhua's 13G Glove Knitting Machine: The Ultimate Solution

Why Choose Changhua?

Changhua, a leading manufacturer of computerized flat knitting machines, has over 20 years of experience in delivering innovative solutions for the textile industry. Our 13G glove knitting machine is designed to address the pain points of labor protection and medical glove manufacturers. Here's why Changhua stands out:

High-Precision Control: Changhua's machines feature advanced digital control systems for precise stitch and tension adjustments.

Seamless Fingertip Technology: The 13G machine uses a sinker knitting system to produce gloves with seamless fingertips, ideal for medical and labor protection applications.

Versatility: Capable of knitting various glove types, including labor protection, medical, and touchscreen gloves, using materials like cotton, polyester, and conductive yarns.

Efficiency: High-speed operation and automated features, such as overlock devices, boost productivity without compromising quality.

Durability: Robust construction and centralized lubrication ensure long-term reliability, even in high-volume production environments.

Key Features of Changhua's 13G Glove Knitting Machine

Computerized Control System

The 13G glove knitting machine is equipped with a Cortex-M4 34 digital microcontroller, which minimizes failure rates and allows for precise programming of glove specifications. Operators can easily set parameters for size, stitch density, and yarn type, ensuring seamless fingertip connections.

Sinker Knitting System

Changhua's sinker system produces gloves with superior elasticity and toughness, ensuring a perfect fit at the fingertips. This is particularly beneficial for medical gloves, where comfort and precision are paramount.

Automatic Overlock Device

The machine's automatic overlock device eliminates manual finishing, reducing labor costs and ensuring a seamless finish at the fingertips. This feature is critical for high-volume production of labor protection gloves.

High-Gauge Precision

With a 13G gauge, the machine produces fine, tight stitches that are ideal for seamless connections. This makes it suitable for applications requiring high manual dexterity, such as medical procedures or technical assembly.

User-Friendly Interface

The 7-inch touchscreen operation panel simplifies setup and monitoring, allowing operators to adjust settings quickly and maintain consistent quality throughout the production process.

Benefits for Manufacturers

By investing in Changhua's 13G glove knitting machine, manufacturers can:

Reduce Labor Costs: Automation features like overlock devices and centralized lubrication minimize manual intervention.

Improve Product Quality: Seamless fingertips enhance comfort, durability, and functionality, meeting the stringent requirements of medical and labor protection industries.

Increase Production Efficiency: High-speed operation and programmable settings allow for rapid production without sacrificing precision.

Meet Diverse Market Needs: The machine's versatility supports a wide range of glove types, from industrial to touchscreen-compatible gloves.

How Changhua Addresses Industry Pain Points

Solving Stitch Precision Issues

Changhua's 13G machine uses high-precision needle beds and cam systems, manufactured with CNC technology and treated with vacuum heat processes. This ensures consistent stitch quality, eliminating gaps or weak points at the fingertips.

Enhancing Yarn Management

The machine's automated yarn-feeding system ensures smooth integration of various yarns, including conductive yarns for touchscreen gloves. This prevents uneven knitting and ensures seamless connections.

Streamlining Calibration

The digital control system allows for real-time adjustments, reducing the need for manual recalibration and ensuring consistent performance across production runs.

Supporting Material Compatibility

Changhua's machine is compatible with a wide range of materials, from cotton and polyester to Kevlar and conductive yarns, making it ideal for producing gloves for diverse applications.

Boosting Production Efficiency

With a daily output of up to 360 pairs, the 13G machine balances speed and precision, enabling manufacturers to meet high-volume demands while maintaining seamless fingertip quality.

Tips for Optimizing Seamless Fingertip Connections

1. Choose the Right Gauge

For seamless fingertips, opt for a high-gauge machine like Changhua's 13G model. Higher gauges produce finer stitches, reducing the likelihood of visible seams.

2. Use Quality Yarns

Select high-quality yarns that are compatible with your machine. For touchscreen gloves, ensure conductive yarns are evenly distributed in the fingertip area.

3. Regular Maintenance

Utilize the machine's centralized lubrication system to keep components in optimal condition, ensuring consistent knitting performance.

4. Fine-Tune Stitch Density

Adjust stitch density settings to match the glove type and material. For medical gloves, tighter stitches are ideal, while labor protection gloves may require slightly looser settings for flexibility.

5. Leverage Automation

Take advantage of automated features like overlock devices and yarn-feeding systems to minimize manual intervention and ensure seamless connections.

Conclusion

Achieving seamless fingertip connections in glove knitting is a critical factor in producing high-quality gloves for labor protection, medical, and fashion applications. High-precision control, enabled by advanced computerized systems, sinker knitting, and high-gauge technology, is the key to overcoming manufacturing challenges. Changhua’s 13G glove knitting machine stands out as a leading solution, offering unparalleled precision, efficiency, and versatility. By investing in Changhua's technology, manufacturers can address industry pain points, improve product quality, and meet the growing demands of diverse markets.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe