The demand for large, intricate, and high-quality blankets—from luxurious throws for the home furnishings market to technical textiles for industrial use—is on the rise. At the heart of meeting this demand lies a specialized piece of technology: the 80–100 inch computerized flat knitting machine. These industrial powerhouses represent the pinnacle of knitting technology, enabling manufacturers to produce wide, seamless, and complex blankets with unparalleled efficiency.

If you're a textile manufacturer, a business owner, or an investor looking to capitalize on this market, understanding this technology is crucial. This ultimate guide will walk you through everything you need to know about large-format blanket knitting. We will start with the fundamentals of the machinery, explore its capabilities, and then delve into why our company, Changhua, is a leading force in manufacturing these innovative machines. Our goal is to provide you with the knowledge to make an informed investment that will propel your business forward.

What is a Computerized Flat Knitting Machine for Blankets?

Before we focus on the large 80-100 inch variants, let's establish a baseline. A computerized flat knitting machine is an electronically controlled device that uses two beds of needles to create knitted fabric. Unlike circular knitting machines that produce tubular fabric, flat knitters create flat panels of fabric, which is ideal for products like blankets, scarves, and apparel pieces.

The "computerized" aspect is what sets modern machines apart. It means every function—from needle selection and carriage movement to yarn feeding and tension control—is managed by a sophisticated computer system. This allows for:

Precision and Complexity: Creating intricate patterns, including jacquard, cables, and lace, with pixel-perfect accuracy.

Reproducibility: Producing thousands of identical blankets without any variation.

Efficiency: Automating the entire process, significantly reducing labor costs and human error.

Why Focus on 80–100 Inch Machines?

The "inch" measurement refers to the knitting width, also known as the machine's gauge in the context of the needle bed length. An 80-inch to 100-inch machine is specifically designed for large-format production.

80-inch machines are excellent for producing standard large blankets and throws without the need for seaming. They offer a great balance of production capacity and floor space requirements.

100-inch machines are the true giants, capable of producing extra-wide blankets, king-sized bedspreads, or even technical textiles like wide industrial fabrics in a single, seamless piece. This eliminates weak points and enhances the product's durability and aesthetic appeal.

Key Advantages of Investing in a Large Blanket Knitting Machine

Upgrading to or investing in an 80-100 inch computerized flat knitting machine can transform your production line. Here are the core benefits:

Seamless Production: The most significant advantage. You can produce an entire blanket in one piece, which is not only stronger but also more comfortable and visually superior to seamed alternatives.

High Production Speed: Equipped with multiple knitting systems (e.g., 2-system, 3-system), these machines can knit courses (rows) with multiple carriages moving simultaneously, drastically increasing output compared to older, single-system machines.

Unmatched Design Flexibility: With advanced jacquard knitting capabilities, the design possibilities are virtually limitless. You can create photorealistic images, complex geometric patterns, and textured designs that were once impossible or prohibitively expensive.

Material Versatility: Modern machines from leading manufacturers like Changhua can handle a wide range of yarns, from natural fibers like wool and cotton to synthetic fibers like acrylic and polyester, as well as fancy yarns for special textures.

Reduced Labor and Waste: Automation leads to a less labor-intensive process. Furthermore, computerized control optimizes yarn usage, minimizing waste and maximizing your profit margins.

Introducing Changhua: Your Partner in Advanced Knitting Technology

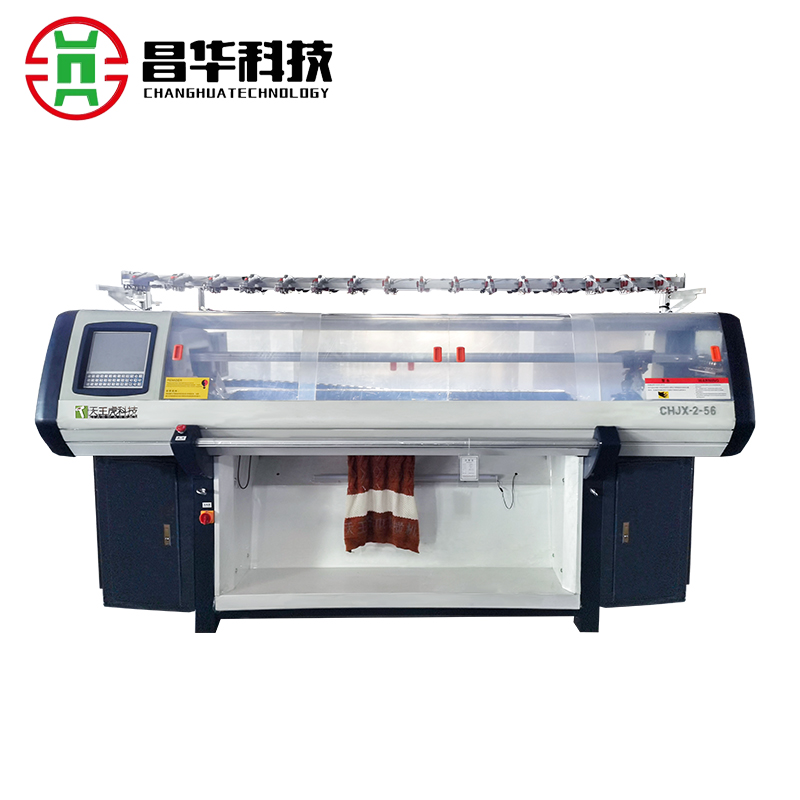

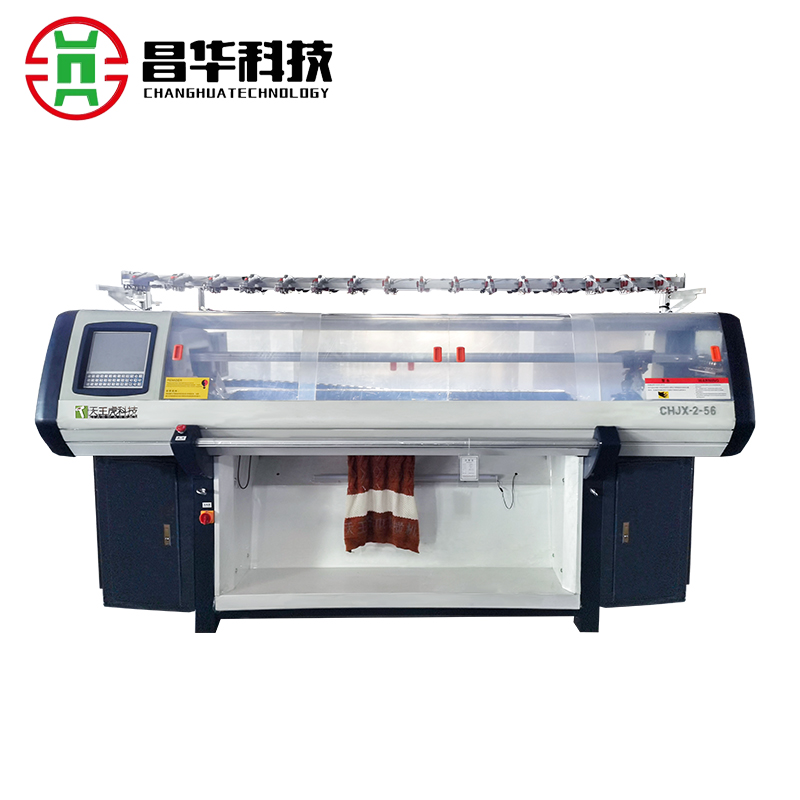

When it comes to reliable, high-performance, and innovative computerized flat knitting machines, our company, Changhua, has built a formidable reputation over the years. We specialize in engineering machines that meet the rigorous demands of modern textile production. Our philosophy is built on three pillars: Innovation, Quality, and Support.

We understand that your machinery is the backbone of your business. That’s why every Changhua knitting machine is designed with precision engineering, user-friendly software, and robust construction to ensure years of dependable service. Our global client base is a testament to our commitment to excellence.

Are you ready to see how our technology can specifically benefit your blanket production? Let's explore some of our flagship models tailored for 80-100 inch knitting.

A Closer Look at Changhua's Premier Blanket Knitting Machines

We offer a range of machines to suit different production volumes and size requirements. Below, we highlight three of our most popular models for large-format blanket production. Each machine is a testament to our engineering prowess.

Model 1: The Efficient Workhorse - 52 Inch Double System Blanket Knitting Machine

While slightly under the 80-inch mark, this model is a crucial part of our range and deserves mention for businesses looking for a high-efficiency machine for large, but not extra-wide, blankets.

This machine is perfect for manufacturers who need to boost productivity without the footprint of a larger machine. The dual systems allow the carriage to knit in both directions, effectively doubling the speed compared to a single-system machine. It's an excellent entry-point into automated, high-speed blanket production.

> > Click here to learn more about the technical specifications of our 52-Inch Double System Machine.

Model 2: The High-Capacity Producer - 80 Inch Three-System Blanket Knitting Machine

This is where true large-format production begins. Our 80-inch three-system machine is a best-seller for a reason. It strikes the perfect balance between width, speed, and versatility.

The three systems take productivity to another level. Imagine producing a high-quality, complex jacquard blanket in a fraction of the time it would take on lesser equipment. This machine is ideal for businesses targeting the home furnishings market, where demand for queen and king-sized throws and blankets is consistently high.

> > Discover the full capabilities and ROI of our 80-Inch Three-System Blanket Knitting Machine on its product page.

Model 3: The Industry Giant - 100 Inch 3+3 System Computerized Blanket Flat Knitting Machine

For manufacturers who require the absolute maximum in width and sophistication, our 100-inch 3+3 system machine is the ultimate solution. This machine is engineered for top-tier production facilities that will not compromise on size or capability.

For manufacturers who require the absolute maximum in width and sophistication, our 100-inch 3+3 system machine is the ultimate solution. This machine is engineered for top-tier production facilities that will not compromise on size or capability.

This machine doesn't just make wide blankets; it makes statement pieces. It's capable of producing extra-wide blankets, oversized throws, and technical fabrics without any seams. The advanced 3system configuration allows for even more complex patterning and structural knitting, giving you a significant competitive edge.

> > For the ultimate in blanket production, explore the detailed features of our 100-Inch 3+3 System Computerized Machine here.

Beyond the Specs: The Tangible Changhua Advantage

While specifications are important, the real value of a Changhua knitting machine lies in the tangible benefits that impact your daily operations and bottom line.

1. Unrivaled Software and Ease of Use

Our machines are powered by intuitive software that simplifies the design process. You can easily import patterns, make adjustments, and control every aspect of the knitting process. Our team provides comprehensive training to ensure your operators are confident and proficient.

2. Superior Build Quality and Durability

We use high-grade materials and precision components in the construction of our machines. This results in minimal vibration, reduced noise levels, and a significantly longer operational lifespan. Investing in a Changhua machine means investing in a asset that will deliver returns for many years.

3. Exceptional After-Sales Support and Global Service

Your relationship with us doesn't end with the sale. We offer robust after-sales support, including readily available spare parts, remote technical assistance, and on-site service options. Our global network ensures that help is never far away.

4. Customization and Technical Expertise

We understand that every production need is unique. Our engineering team can work with you to discuss potential customizations or recommend the perfect machine configuration for your specific yarns and products.

Frequently Asked Questions (FAQ) About Blanket Knitting Machines

Q1: What kind of yarns can a Changhua machine handle?

A: Our machines are highly versatile and can process a wide array of yarns, including acrylic, wool, cotton, polyester, and blended yarns. The specific yarn type and count will depend on the machine's gauge. We can advise you on the best match for your product.

Q2: How difficult is it to learn the operating software?

A: Our software is designed with user-friendliness in mind. While there is a learning curve with any advanced machinery, we provide detailed training materials and hands-on training sessions to ensure your team can operate the machine effectively.

Q3: What is the typical delivery and installation timeline?

A: Timelines can vary based on the model and order volume. We strive for efficient production and delivery. Please contact our sales team for a precise timeline based on your requirements.

Q4: Do you offer a warranty?

A: Yes, all Changhua machines come with a comprehensive warranty. We stand behind the quality of our products.

Ready to Transform Your Blanket Production? Get Your Quote Today!

The world of textile manufacturing is competitive. Staying ahead requires investing in technology that boosts efficiency, quality, and creativity. Changhua's range of 80-100 inch computerized flat knitting machines offers a proven path to achieving these goals.

We invite you to take the next step. Whether you need more detailed specifications, would like to see the machines in action via a video call, or are ready to discuss a customized solution, our team is here to help.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe