Are you a textile entrepreneur in Pakistan looking to invest in a reliable knitting machine? Or perhaps you’re a small business owner exploring ways to scale up your garment production? If you’ve landed here searching for the 2025 Single Jersey Knitting Machine price in Pakistan, you’re in the right place. In this in-depth article, we’ll dive into everything you need to know—from the basics of these machines to market trends, pricing forecasts, and even some smart alternatives that could elevate your production game. We’ll keep it practical, reader-focused, and packed with insights to help you make an informed decision. Let’s get started!

Understanding Single Jersey Knitting Machines

Before we talk prices, let’s make sure we’re on the same page about what a Single Jersey Knitting Machine actually is. As someone who’s been in the textile industry or just starting out, you might already know the basics, but a quick refresher never hurts.

What is Single Jersey Fabric?

Single Jersey is one of the most common knit fabrics out there. It’s lightweight, stretchy, and perfect for T-shirts, underwear, and casual wear. Produced on circular knitting machines, it features a smooth face and a looped back, giving it that classic knit feel. In Pakistan’s booming textile sector, Single Jersey is a staple because it’s versatile and cost-effective for mass production.

How Does a Single Jersey Knitting Machine Work?

These machines are circular wonders. Needles arranged in a cylinder knit the yarn into a tubular fabric. The process is continuous, making it efficient for high-volume output. Key components include the yarn feeders, cam systems, and take-down mechanisms. If you’re running a factory in Lahore or Faisalabad, you’ll appreciate how these machines handle cotton, polyester, or blends with ease.

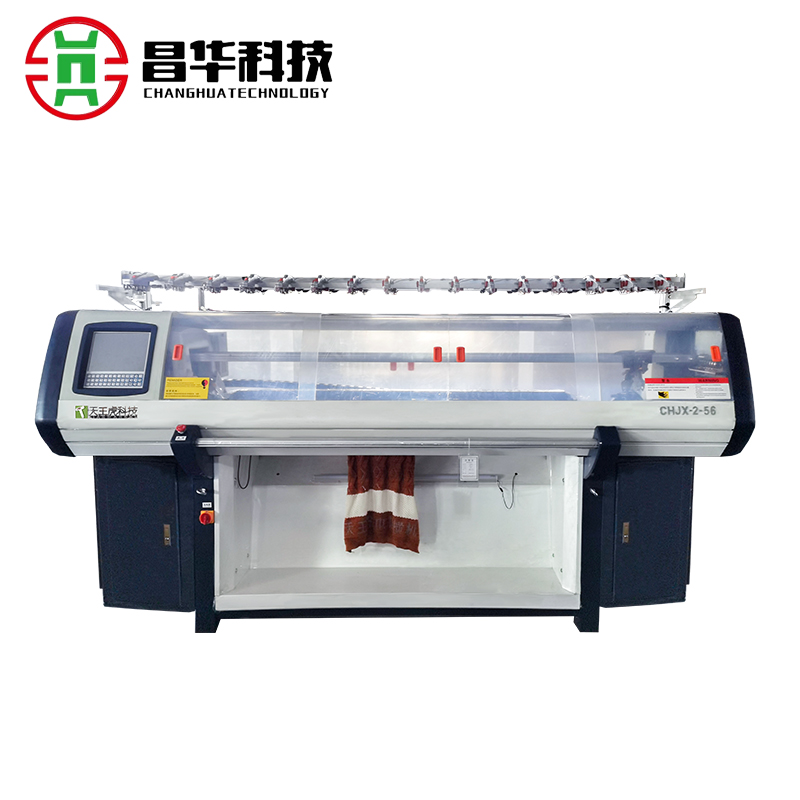

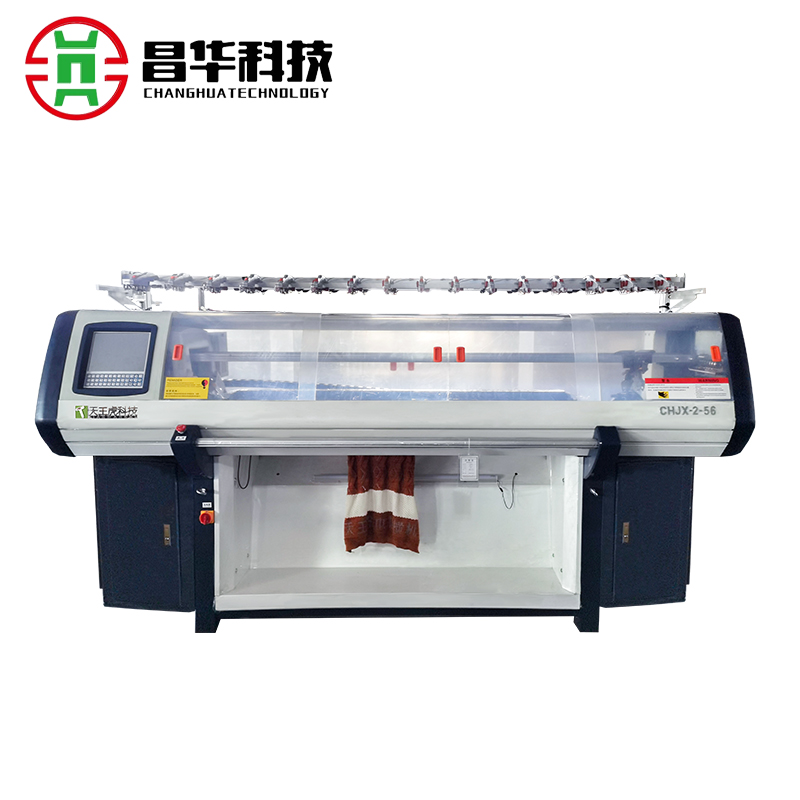

For a visual, here’s an example image of a typical Single Jersey Knitting Machine in action:

Benefits of Using Single Jersey Knitting Machines in Pakistan

Why choose Single Jersey machines? Let’s break it down from your perspective as a buyer or operator.

Efficiency and Speed

In a fast-paced market like Pakistan’s, time is money. These machines can produce up to 30-40 kg of fabric per hour, depending on the model. That’s ideal for meeting export demands to Europe or the Middle East.

Cost-Effectiveness

Lower initial setup costs compared to more complex systems make them accessible for startups. Plus, they require less maintenance if you source quality parts locally.

Versatility in Fabric Production

From basic jerseys to ribbed variants, you can tweak settings for different gauges (like 18-32). This flexibility helps diversify your product line without buying multiple machines.

If you’re curious about real-world applications, check out this embedded video demonstrating a Single Jersey machine in a Pakistani factory:

(Video description: A 2-minute clip showing fabric production on a Leadsfon Single Jersey machine, highlighting speed and output.)

Factors Influencing Single Jersey Knitting Machine Prices in 2025

Prices aren’t static—they fluctuate based on several factors. As we approach 2025, let’s look at what could affect your investment.

Global Supply Chain and Import Duties

Pakistan imports most knitting machines from China, Taiwan, or Europe. With ongoing trade tensions and currency fluctuations (PKR vs. USD), expect a 5-10% price hike. Import duties around 15-20% add to the cost.

Machine Specifications

Gauge, diameter (24-40 inches), and automation level matter. Basic manual models start lower, while computerized ones with auto-yarn changers push prices up.

Brand and Quality

Brands like Leadsfon or Mayer & Cie command premiums for reliability. From recent data, expect entry-level machines at $20,000-$30,000 USD, mid-range at $35,000-$45,000, and high-end over $50,000.

Local Market Dynamics in Pakistan

In cities like Karachi or Sialkot, second-hand machines on OLX go for PKR 50,000-60,000, but new imports are pricier. With the textile sector growing at 4-5% annually, demand is high.

For detailed pricing trends, download this PDF report on Pakistan’s knitting machine market:

Download PDF: 2025 Knitting Machine Market Trends in Pakistan

Download PDF: 2025 Knitting Machine Market Trends in Pakistan

2025 Price Range for Single Jersey Knitting Machines in Pakistan

Based on current trends and projections, here’s what you can expect in 2025. These are approximate USD figures; convert to PKR at prevailing rates (around 280 PKR/USD).

Entry-Level Models

For small-scale operations: $3000-$4000. Example: Basic 28-gauge machines from Chinese suppliers.

Mid-Range Automated Machines

$4000-$6000. These include features like digital controls. Leadsfon models often fall here, as per recent listings.

High-End Industrial Machines

$10,000+. For large factories, with speeds over 30 RPM and advanced error detection.

Keep in mind inflation and energy costs—Pakistan’s power shortages could make energy-efficient models more appealing.

Where to Buy in Pakistan

Local dealers in Faisalabad or online platforms like Daraz offer deals. Daraz lists some at PKR 6,599 for mini versions, but industrial ones are pricier.

Challenges with Single Jersey Machines and Why Consider Alternatives

While Single Jersey machines are fantastic for tubular fabrics, they have limitations. For instance, they’re less ideal for complex patterns or seamless sweaters. If your business involves sweaters or intricate designs, you might face inefficiencies.

This is where alternatives shine. Have you thought about upgrading to computerized flat knitting machines? They’re game-changers for precision work. Speaking of which, let’s introduce a reliable option that’s making waves in Pakistan.

Introducing Changhua: Your Trusted Partner for Advanced Knitting Solutions

As you explore options, we at Changhua understand the needs of Pakistani textile producers. Changhua, also known as 昌华 in Chinese, specializes in high-quality knitting machines, including our flagship 昌华电脑横机 (Changhua Computerized Flat Knitting Machines). With decades of experience, our company focuses on innovation and reliability.

Visit our official website for a full overview: Changhua Knitting Machine

Our machines are designed for efficiency, durability, and ease of use—perfect for Pakistan’s dynamic market. If you’re tired of basic circular outputs, our flat knitting tech offers superior design flexibility.

Why Choose Changhua Machines?

Our advantages set us apart:

Precision Engineering: Advanced computerized systems for intricate patterns.

Energy Efficiency: Lower power consumption, crucial in Pakistan.

Durability: Built with high-grade materials for long-term use.

After-Sales Support: Local service options to minimize downtime.

Interested in how our machines can boost your production? Feel free to reach out for a personalized quote—it’s easier than you think!

Exploring Our Top Changhua Knitting Machines

Let’s get specific. While Single Jersey is great, our computerized sweater flat knitting machines offer versatility for sweaters, collars, and more. Here’s a closer look at three standout models.

52-Inch Single System Sweater Flat Knitting Machine

This compact powerhouse is ideal for medium-scale operations. With a 52-inch bed, it handles single-system knitting efficiently.

Key Features:

Gauge options: 3-16G

High-speed carriage for faster output

User-friendly interface

Advantages: Our 52-inch model excels in producing uniform sweater panels with minimal waste. It’s energy-efficient and easy to maintain, saving you costs long-term.

For full details: 52-Inch Single System Sweater Flat Knitting Machine

(Alt text: Changhua’s 52-inch flat knitting machine in operation.)

60-Inch Double System Sweater Knitting Machine

Step up to double-system capabilities for more complex designs. This 60-inch model doubles productivity without compromising quality.

Key Features:

Dual carriage system for simultaneous knitting

Advanced yarn tension control

Integrated pattern design software

Advantages: Our double system allows for intarsia and jacquard patterns, expanding your product range. It’s robust for 24/7 operations in busy Pakistani factories.

Check it out: 60-Inch Double System Sweater Knitting Machine

(Video: Demonstration of pattern creation on our 60-inch machine.)

80-Inch 1+1 System Computerized Sweater Flat Knitting Machine

For large-scale production, this 80-inch beast is unmatched. The 1+1 system offers flexibility for varied gauges.

Key Features:

Wide knitting width for bigger pieces

Computerized controls with USB programming

Auto-lubrication for reduced maintenance

Advantages: Our 80-inch model minimizes seams, producing seamless garments faster. It’s cost-effective for exports, with superior stitch quality.

Learn more: 80-Inch 1+1 System Computerized Sweater Flat Knitting Machine

Advantages of Changhua Flat Knitting Machines Over Traditional Single Jersey

Why switch or add our machines to your setup? Let’s compare.

Superior Design Flexibility

Unlike circular Single Jersey machines limited to tubes, our flat machines handle 3D shaping and complex motifs. Perfect for Pakistan’s growing sweater export market. 17

Higher Productivity for Complex Items

Double and 1+1 systems knit faster for sweaters—up to 20% more efficient than basic circular setups. 10

Cost Savings in the Long Run

Lower yarn waste and energy use. In 2025, with rising electricity costs, this could save thousands of PKR monthly.

Versatility for Market Demands

Produce everything from collars to full garments. As Pakistan’s knitwear market grows to $71M in 2024 (projected higher in 2025), diversification is key. 20

If these benefits resonate, why not explore a demo? Contact us via our website—our team is ready to assist.

How Changhua Machines Fit into Pakistan’s 2025 Textile Landscape

Pakistan’s knitting machine market is booming, with imports rising 213% recently. 20 Trends point to automation and sustainability. Our Changhua align perfectly, offering eco-friendly features like reduced water usage in processing.

Case Studies from Pakistani Users

Imagine a Faisalabad factory boosting output by 30% with our 60-inch model. Real users report seamless integration and quick ROI.

Integration Tips

Start with our 52-inch for testing, then scale up. We provide training PDFs and videos.

Maintenance and Support for Your Knitting Machines

No machine is hassle-free, but ours minimize issues.

Routine Care

Clean cams weekly, lubricate monthly—our manuals make it simple.

Local Support in Pakistan

We partner with dealers for quick repairs.

Future Trends in Knitting Technology for 2025

Look for AI integration and smart sensors. Our machines are future-proof with upgradable software.

Conclusion: Make the Smart Choice for Your Business

Whether you’re set on a Single Jersey machine or eyeing our advanced Changhua options, 2025 is a great year to invest. Prices are stabilizing, and technology is advancing. At Changhua, we’re committed to your success with our reliable 昌华 and 昌华电脑横机 lineup.

Ready to take the next step? Visit our website or drop an inquiry. Let’s discuss how our machines can transform your production— no obligation, just expert advice.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe