Knitting sweaters with a knitting machine can significantly reduce production time compared to hand knitting. The exact time depends on several factors, including the machine type, sweater complexity, yarn choice, and operator skill.

Manual Knitting Machines: 4–8 hours per sweater

Semi-Automatic Machines: 2–4 hours per sweater

Fully Automated Machines: 30 minutes–2 hours per sweater

For mass production, industrial knitting machines can produce hundreds of sweaters per day.

Factors Affecting Sweater Production Time

1. Type of Knitting Machine

Flat Knitting Machines: Best for custom designs, slower than circular machines.

Circular Knitting Machines: Faster, ideal for seamless sweaters.

Computerized Knitting Machines: High-speed, programmable for complex patterns.

2. Sweater Design Complexity

Simple designs (plain knit) are faster.

Intricate patterns (cables, jacquard) take longer.

3. Yarn Type and Thickness

Thicker yarn knits faster but may require fewer stitches.

Fine yarn takes longer but produces lightweight sweaters.

4. Operator Experience

Skilled operators can adjust settings for efficiency.

5. Finishing Processes

Linking seams

Washing & blocking

Adding buttons or embroidery

Recommended Knitting Machines for Faster Production

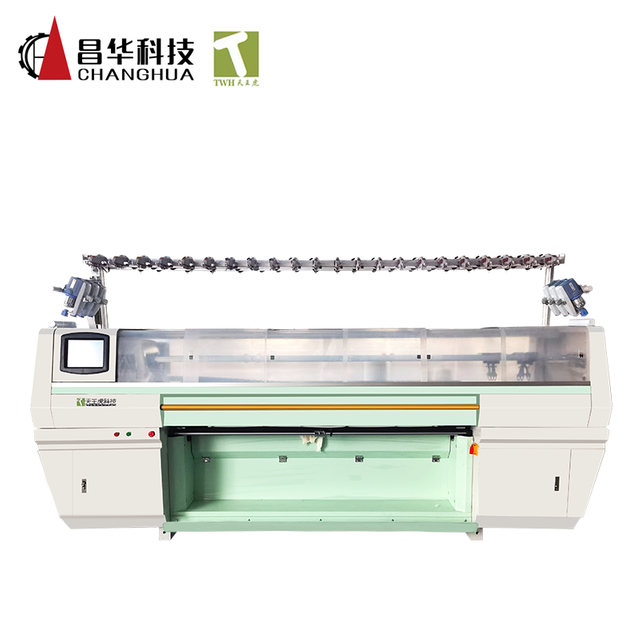

For high-quality and efficient sweater production, Changhua knitting machines are a top choice. Known for durability and precision, they offer:

High-speed circular knitting machines for seamless sweaters.

Computerized flat knitting machines for intricate designs.

Energy-efficient models to reduce production costs.

Learn more about Changhua knitting machines

What Is the Process of Knitwear Manufacturing?

Knitwear manufacturing involves multiple stages, from yarn selection to final packaging. Below is a detailed breakdown.

1. Yarn Selection & Preparation

Yarn Sourcing: Wool, cotton, acrylic, or blends.

Yarn Testing: Strength, elasticity, and colorfastness checks.

Winding: Yarn is wound onto cones for machine use.

Pro Tip: High-quality yarn reduces defects in the final product.

2. Knitting Process

a. Setting Up the Knitting Machine

Needle configuration based on sweater size.

Loading yarn onto the machine.

b. Knitting the Fabric

Flat Knitting: Produces panels (front, back, sleeves).

Circular Knitting: Creates seamless tubes (body & sleeves).

c. Quality Control During Knitting

Checking for dropped stitches or tension issues.

3. Cutting & Assembling (If Using Flat Knit Panels)

Panels are cut to shape.

Sewn together using linking machines for a seamless look.

4. Washing & Dyeing (If Needed)

Removes oils and softens the fabric.

Dyeing for desired colors.

5. Finishing Touches

Blocking: Shapes the sweater.

Adding Trims: Buttons, zippers, embroidery.

Final Inspection: Ensures no defects.

6. Packaging & Shipping

Folding, tagging, and boxing for retail.

Watch:How Sweaters Are Made in a Factory

Download: Knitwear Manufacturing Guide (PDF)

Why Choose Changhua Automated Knitting Machines?

Faster production (up to 10x quicker than hand knitting).

Consistent quality (fewer human errors).

Cost-effective for bulk orders.

Best Machines for Sweater Production

| Machine Type | Speed | Best For |

| Flat Knitting | Medium | Custom designs |

| Circular Knitting | Fast | Seamless sweaters |

| Computerized | Very Fast | Complex patterns |

Changhua Knitting Machines offer advanced automation for large-scale production.

Conclusion

Making a sweater with a knitting machine can take anywhere from 30 minutes to 8 hours, depending on the machine type and design complexity. The knitwear manufacturing process involves yarn preparation, knitting, assembly, finishing, and packaging. For businesses looking to scale production, automated knitting machines like those from Changhua provide speed, precision, and cost efficiency.

Want to start your own knitwear production? Please contact us. We look forward to your visit and consultation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe