The textile industry thrives on innovation, precision, and efficiency, particularly when it comes to producing high-quality blankets. Blanket knitting machines have revolutionized how manufacturers create plush, durable, and aesthetically pleasing blankets for home decor, fashion, and industrial applications. Among the various technologies available, multi-system knitting machines stand out for their ability to handle complex patterns, diverse materials, and large-scale production. This article explores the multi-system knitting process, compares three key machine types—Double System, Three System, and 3+3 System—and provides actionable insights for home textile businesses to select the ideal equipment. We'll also highlight how Changhua's cutting-edge blanket knitting machines, available at Changhua Blanket Knitting Machines, meet diverse production needs, whether working with wool, synthetic fibers, or blended yarns.

What Are Blanket Knitting Machines?

Blanket knitting machines are specialized textile equipment designed to produce flat, wide fabrics ideal for blankets, throws, and afghans. Unlike circular knitting machines that create tubular fabrics, flatbed knitting machines excel at crafting large, seamless panels with intricate patterns and textures. These machines are equipped with advanced features like computerized controls, dynamic stitch adjustments, and high-performance rollers, enabling manufacturers to produce everything from cozy baby blankets to luxurious jacquard throws.

Key Applications of Blanket Knitting Machines

Blanket knitting machines serve a wide range of industries and purposes, including:

Home Textile Industry

Producing blankets, throws, and bedding items like duvet covers and pillowcases for residential use.

Fashion Industry

Creating stylish, patterned blankets and shawls that double as fashion accessories.

Hospitality Sector

Manufacturing durable, high-quality blankets for hotels, resorts, and spas.

Industrial Applications

Crafting technical textiles, such as fire-resistant or insulated blankets for specialized uses.

Why Multi-System Knitting Matters

Multi-system knitting refers to the use of multiple knitting systems within a single machine cycle, allowing for complex pattern creation and enhanced production efficiency. The number of systems—Double, Three, or 3+3—determines the machine’s capability to handle intricate designs, rib transfers, jacquard patterns, and needle narrowing. This flexibility is crucial for businesses seeking to produce blankets with unique textures, such as pointelle, tuck, or intarsia, while maintaining high output and consistent quality.

The Multi-System Knitting Process Explained

How Multi-System Knitting Works

Multi-system knitting machines operate with multiple sets of needles and yarn feeders that work simultaneously or in sequence to create complex fabric structures. Each system controls a specific aspect of the knitting process, such as stitch formation, pattern creation, or tension adjustment. Here’s a breakdown of the process:

Yarn Feeding: Multiple yarn feeders supply different types or colors of yarn (e.g., wool, synthetic fibers) to create varied textures and patterns.

Needle Bed Operation: The flat needle bed moves back and forth, with needles knitting rows of fabric. Multi-system machines have two or more needle beds, enabling simultaneous knitting of front and back layers or complex patterns.

Digital Control: Computerized systems manage stitch types, pattern designs, and tension settings, ensuring precision and consistency.

Roller Systems: Advanced rollers, like Changhua’s fully formed combined roller, control transverse tension and bed alignment, ensuring uniform fabric output.

Pattern Creation: Techniques like jacquard, intarsia, and rib transfer allow for intricate designs, from simple ribbed textures to elaborate multi-color patterns.

Benefits of Multi-System Knitting

Versatility: Supports a wide range of patterns, including pointelle, tuck, jacquard, and intarsia.

Efficiency: Multiple systems reduce knitting time, boosting production rates.

Precision: Digital controls ensure consistent stitch quality and minimal errors.

Material Flexibility: Compatible with wool, cotton, synthetic fibers, and blends, meeting varied market needs.

Sustainability: Reduces material waste by knitting precise shapes and minimizing post-production sewing.

Comparing the Three Machine Types: Double System, Three System, and 3+3 System

Choosing the right blanket knitting machine depends on your production goals, budget, and material preferences. Below, we compare the three main types offered by Changhua, focusing on their features, advantages, and ideal use cases.

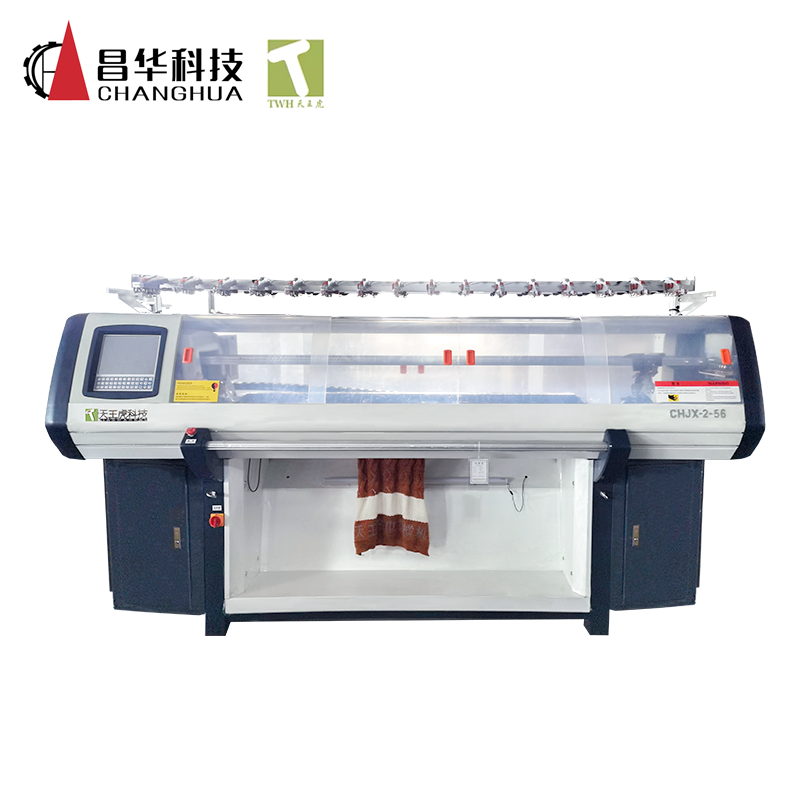

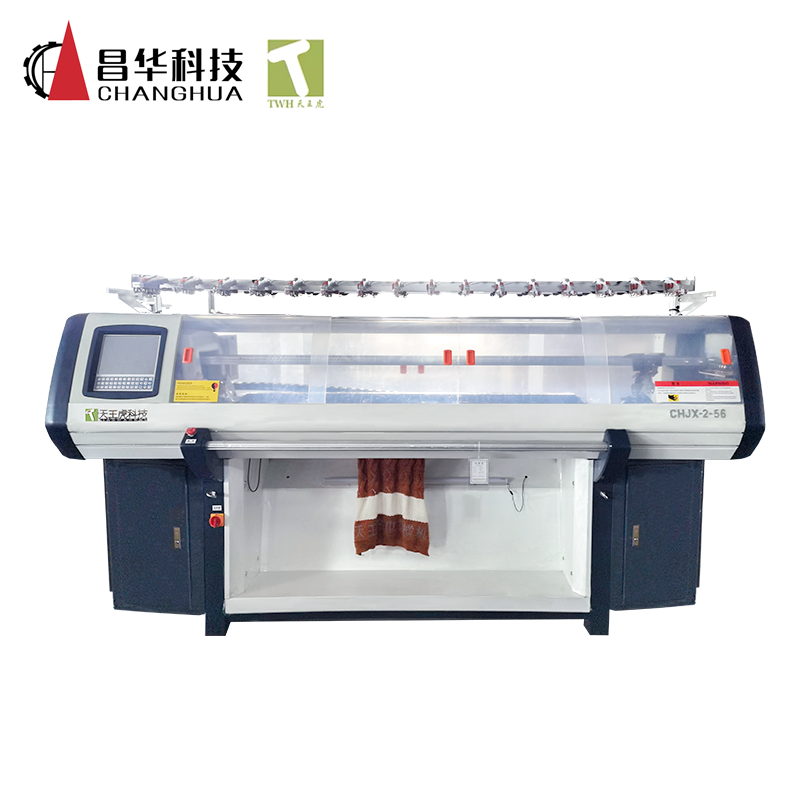

Double System Blanket Knitting Machine

Overview

The Double System machine, as described on Changhua's website, features two knitting systems with high rollers, high-performance sinkers, dynamic stitch control, and motor-controlled reserving carriages. It leverages digital technology for high-speed, efficient production of complex patterns like pointelle, tuck, jacquard, and intarsia.

Key Features

High Roller and Sinker System: Ensures smooth fabric output and precise tension control.

Digital Technology: Enables fast programming and pattern customization.

Material Compatibility: Works with wool, cashmere, cotton, chemical fibers, and blends.

Applications: Ideal for sweaters, blankets, scarves, gloves, hats, and apparel accessories.

Advantages

Cost-Effective: Lower initial investment compared to higher-system machines, making it suitable for small to medium-sized businesses.

High Speed: Achieves efficient production for standard blanket designs.

Ease of Use: User-friendly interface, ideal for manufacturers new to computerized knitting.

Three System Blanket Knitting Machine

Overview

The Three System machine, includes advanced features like rib transfer jacquard, needle narrowing, and weaving functions for basic and complex patterns. It comes in two models: with or without a comb, offering flexibility for different production needs.

Key Features

Rib Transfer and Jacquard: Supports intricate patterns and textures, ideal for premium blankets

Milling-Type Needle Bed: Enhances precision for knitting collars, ribs, and flat fabrics.

Digital Technology: Facilitates knitting of square semi-jacquard, line patterns, and full tuck designs.

Material Compatibility: Suitable for spun silk, synthetic filaments, wool, acrylic, and blends.

Advantages

Enhanced Pattern Complexity: Offers greater design flexibility for high-end blankets.

Precision for Collars and Ribs: Solves issues like unclear fabric lines or uneven edges, ensuring professional-grade output.

Versatility: Balances speed and complexity, suitable for both mass production and custom designs.

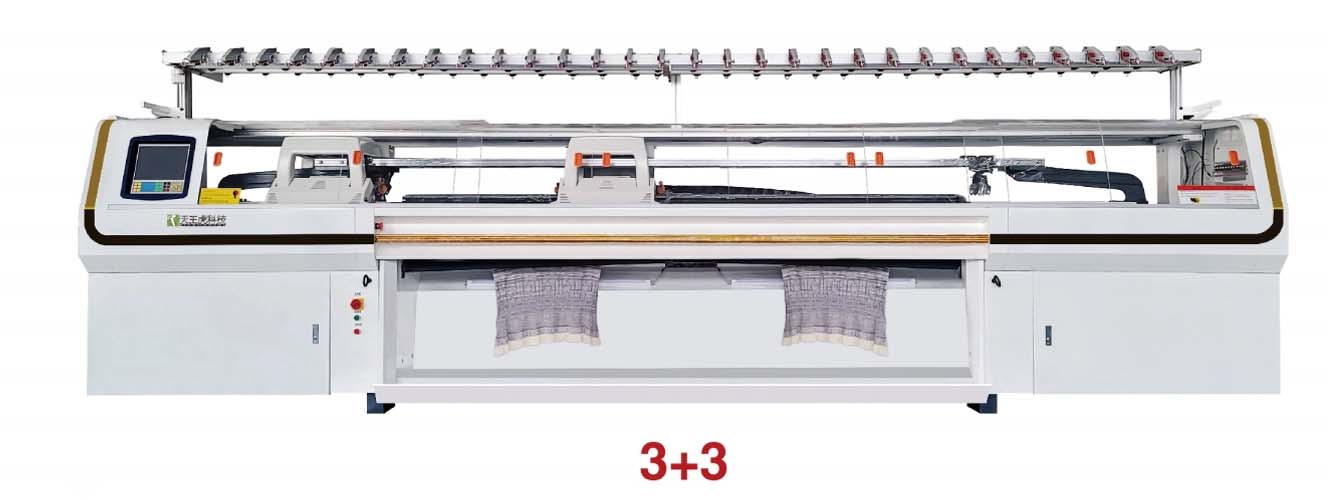

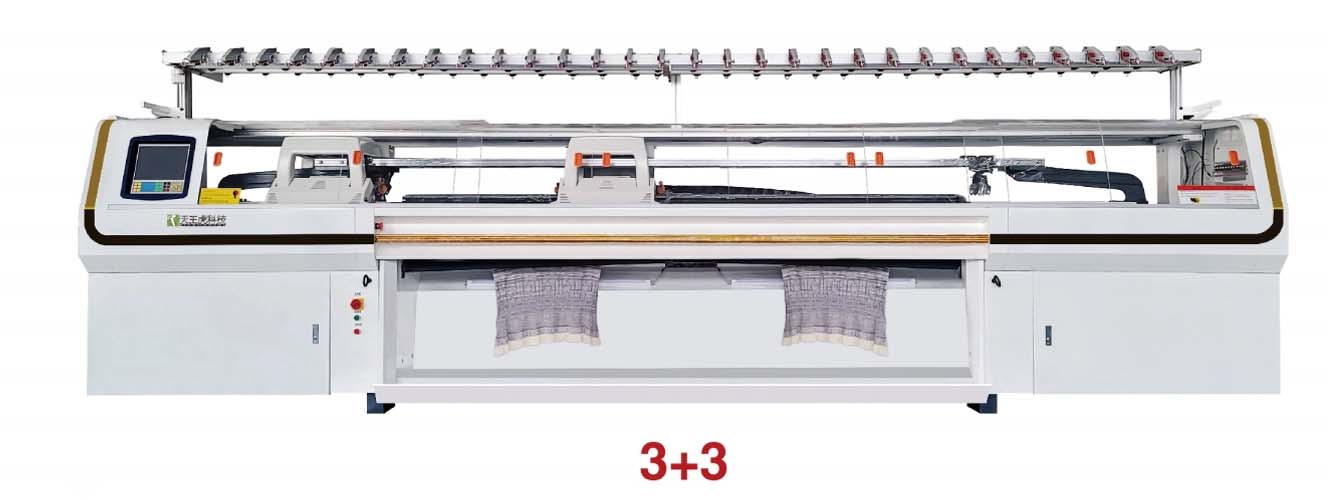

3+3 System Blanket Knitting Machine

Overview

The 3+3 System machine, such as Changhua's 100 Inch 14G model, is the most advanced option, designed for high-volume production of large, complex blankets. It features six knitting systems (3+3 configuration) for unparalleled efficiency and pattern versatility.

Key Features

Six-System Configuration: Doubles the knitting capacity of a Three System machine, enabling faster production of large blankets.

High Roller and Dynamic Stitch: Supports pointelle, tuck, jacquard, intarsia, and full needle jacquard patterns.

Fully Formed Combined Roller: Separately controls transverse tension and front/rear beds, ideal for whole-garment knitting.

Material Compatibility: Handles wool, cashmere, cotton, chemical fibers, and blends with ease.

Advantages

Maximum Efficiency: Ideal for large-scale production with minimal downtime.

Seamless Whole-Garment Knitting: Reduces post-production sewing, saving time and labor.

Sustainability: Minimizes material waste, aligning with eco-friendly production goals.

Why Choose Changhua's Blanket Knitting Machines?

About Changhua

Changshu Changhua Smart Manufacturing Technology Co., Ltd., based in Changshu, Jiangsu, has over 20 years of experience in developing advanced knitting machinery. With a mission to modernize the knitting industry, Changhua produces high-quality machines under brands like “Changhua,” “Tiangong,” “King Tiger,” and “Miao’s Craftsman.”Our blanket knitting machines are trusted globally for our durability, innovation, and performance.

Key Benefits of Changhua's Machines

Advanced Technology

Computerized controls and dynamic stitch systems ensure precision and efficiency.

Durability

Automatic oiling systems reduce wear on needle beds, extending machine lifespan.

Global Support

Changhua offers installation, training, and maintenance services worldwide.

Sustainability

Machines are designed for minimal waste, supporting eco-friendly production.

Versatility

Compatible with a wide range of yarns, from wool to synthetic fibers, meeting diverse market needs.

How to Choose the Right Blanket Knitting Machine

Factors to Consider

Production Volume:

Small to Medium: Double System machines offer cost-effective, high-speed production for startups or niche markets.

Large-Scale: 3+3 System machines are ideal for high-volume production with complex designs.

Balanced Needs: Three System machines provide a mix of speed, complexity, and versatility.

Material Requirements:

Wool and Cashmere: All three systems handle natural fibers well, but the 3+3 System excels for seamless, high-end blankets.

Synthetic Fibers: Double and Three System machines are efficient for chemical fibers and blends, offering cost savings.

Blended Yarns: All systems support blends, with the Three and 3+3 Systems offering superior pattern control.

Pattern Complexity:

Simple Designs: Double System machines are sufficient for basic ribbed or plain blankets.

Intricate Patterns: Three and 3+3 System machines support jacquard, intarsia, and rib transfer for premium designs.

Budget:

Entry-Level: Double System machines are the most affordable, ideal for startups.

Mid-Range: Three System machines balance cost and advanced features.

Premium: 3+3 System machines require higher investment but deliver unmatched efficiency and output.

Sustainability Goals:

Decision-Making Checklist

Assess Production Goals: Determine your target output and market (e.g., mass production vs. bespoke designs).

Evaluate Material Needs: Match the machine to your primary yarn types (wool, synthetic, or blends).

Consider Automation: Computerized machines like Changhua's reduce manual labor and improve consistency.

Check Support Services: Ensure the manufacturer provides training, maintenance, and spare parts.

Test Durability: Opt for machines with automatic oiling and high-quality components to minimize downtime.

Practical Tips for Home Textile Businesses

Optimizing Production with Changhua Machines

Automate Pattern Design: Use Changhua’s computerized controls to store and recall patterns, reducing setup time.

Maintain Equipment: Regular cleaning and oiling, as supported by Changhua’s automatic systems, extend machine lifespan.

Train Staff: Leverage Changhua’s on-site and online training to ensure operators maximize machine capabilities.

Troubleshooting Common Issues

Uneven Stitches: Check needle alignment and yarn tension, as recommended by Changhua’s troubleshooting guide.

Machine Jamming: Clean lint and oil moving parts regularly to prevent downtime.

Software Errors: Update firmware and reset settings for smooth operation.

Conclusion

Selecting the perfect blanket knitting machine is a critical decision for home textile businesses aiming to balance quality, efficiency, and cost. Changhua's Double System, Three System, and 3+3 System machines offer tailored solutions for diverse production needs, from cost-effective standard blankets to high-volume, seamless premium designs. By understanding your production goals, material preferences, and budget, you can choose the ideal machine to elevate your business.

Visit Changhua's Blanket Knitting Machine page to explore these advanced machines and download detailed guides to inform your decision. With Changhua’s 20+ years of expertise, global support, and commitment to sustainability, you’re equipped to lead the textile industry with high-quality, innovative blankets.

Call to Action: Contact Changhua today to consult with our experts and find the perfect blanket knitting machine for your business.  Download our comprehensive PDF guide.pdf and start revolutionizing your production process!

Download our comprehensive PDF guide.pdf and start revolutionizing your production process!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe